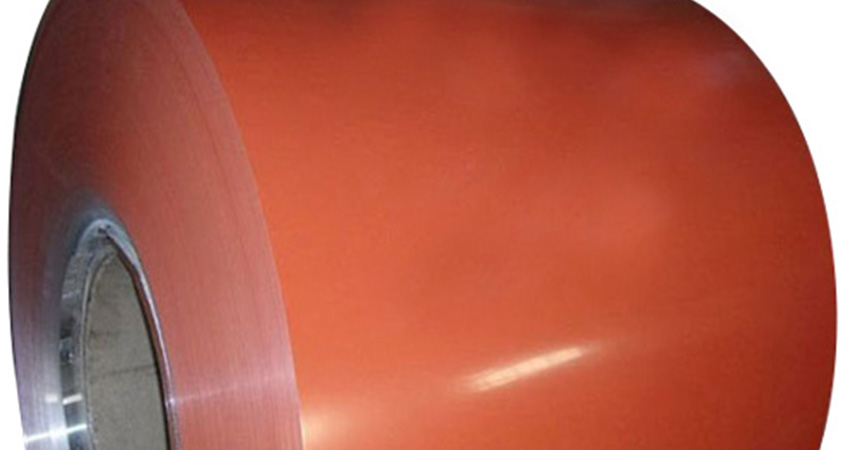

Alloys and prices for pe coated aluminum coil

Alloys for aluminum coated coil pe include 3003, 3005, 5005, 1100 etc. The price varies from specification to specification, the lowest only $2200 per metric ton. Details are as below. 3003 and 3005 aluminium alloy are two representatives of 3000 series, known as an anti-rust material. The difference between 3xxx and 1xxx lies in the fact that the anti-rust ability …

1100 pe pdvf grey white color coated aluminum coil

1100 pe pdvf grey white color coated aluminum coil is obtained by coating the surface of 1100 alu coil with pe or pvdf paints of grey or white color. The most popular application for it is roofing. 1100 aluminum coil contains 99% aluminium and 1% other metals, falling on the pure aluminum series. Owing to high aluminium content, its strength …

Black aluminum coil advantages and application

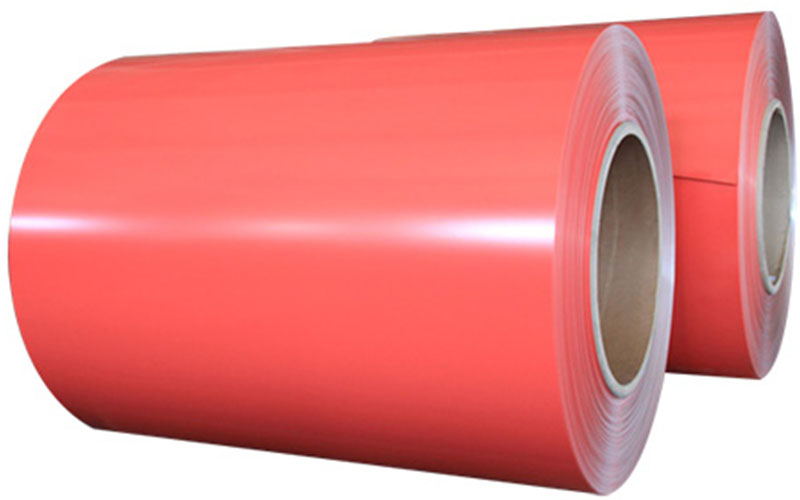

A black aluminum coil is a kind of coated aluminium coil stocks processed by color coating or anodizing methods. A coated aluminium coil has PE or PVDF coating on the surface, obtained by sending mill finish aluminum coil stocks into painting rollers, and an anodized aluminum roll has a film layer. The thin layer of the oxide film has a …

New order of 1060 color coated aluminum coils from Philippines

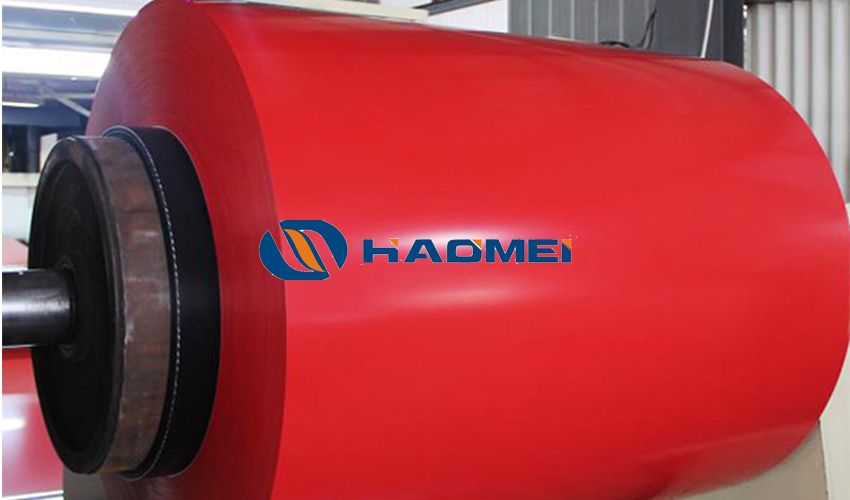

Days ago we received a new order for 20-ton PE 1060 color coated aluminum coils from the Philippines. The client is a roofing sheet manufacturer in local market. 1060 color coated alu coil is among the cheapest and softest painted aluminium series. It contains 99.6% aluminium, and can be painted with PE or PVDF. PE coating thickness is 18 micron …

What is pvc color coated aluminum trim coil

The PVC aluminum trim coil refers to a color coated aluminum coil whose surface or surfaces are coated with pvc paint. PVC paint is the abbreviation of English Polyvinyl Chloride, which is also known as polyvinyl chloride. Using amorphous materials as raw materials, it has excellent properties in oxidation resistance, strong acid resistance and resistance to reduction. Polyvinyl chloride also …

Color coated aluminum coil purchasing tips

Aluminum coil is a metal product obtained by continuous rolling and tension leveling of raw materials, applied extensively in electronic, packing, construction and machinery industries. The manufacturing process of China aluminum coil suppliers goes toe to toe with that from developed countries in the world. With increasingly widened application scope, aluminum coil has been further divided into many secondary categories, …

Advantages of Color Coated Aluminum Coils

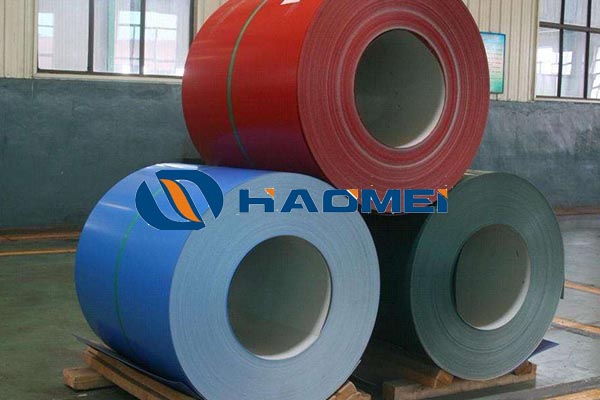

The color coated aluminum coil is a relatively popular product in the aluminum market. Because of its good cost performance, it is widely used in areas of aluminum ceilings, roofing surfaces, trims, cans, aluminum veneers and the like. Advantages of the coil include advanced technology, high folding resistance, strong decorative effect, strong weather resistance and light weight. 1. Advanced technology …

Roller Coating Process of PVDF Color Coated Aluminum Coil

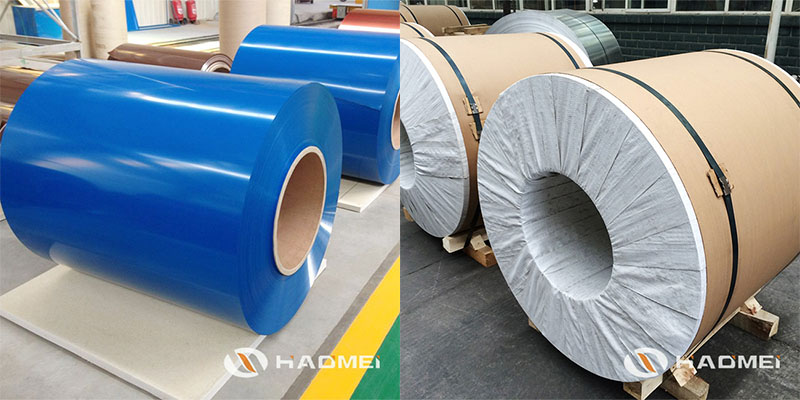

The roll coating process is an effective method to coat color coated aluminum with organic protective coatings. As a continuous and highly automated process, it helps to produce pvdf color coated aluminum coil rolls of better consistency than those from post-coating methods. Typical coating line systems require aluminium substrates of good moulding property, satisfying scratch-proof ability, beautiful appearance, excellent weather …

PVDF Color Coated Aluminum Coil Manufacturers

In the past years the color coated aluminum industry in China has developed rapidly. No matter how many factories there are, some problems still exist with color coated coil manufacturers, including coil thickness, product class, industry normalization and production line stability. Restricted by backward technology, few manufacturers in China are able to supply pvdf color coated aluminum coil of thickness …

3003 PVDF Color Coated Aluminum Coil for Beverage Cans

3003 pvdf color coated aluminum coil is a regular product for beverage cans. It has good corrosion resistance, workability, printing ability and light weight. 3003 aluminum coil contains a certain content of manganese that is known for excellent corrosion resistance. As the most widely applied anti-rust aluminum coil, 3003 is not suitable for heat treatment, thus cold processing is the …

Color Coated Aluminum Strip Coils

Color coated aluminum strip coils refer to aluminum flat strap rolls with coated paints. Coated aluminum coil is also known as aluminum trim coil. Color coated aluminum strip is actually narrow aluminum trim coil. Regular alloys for it include 1050, 1060, 1070, 1100, 3003, 3004, 5052, 5005 and 5083 etc. The surface of the strip has been anodized before being …

How to Avoid Impurities in Color Coated Aluminum Coil Further Process

Most aluminum extrusion manufacturers adopt forward heat deformation squeezing methods in further processing of color coated aluminum coils. The rolls go through specialized molds (flat, prod or divergent dies) and become profiles of corresponding shapes. In such a process impurities come into being on the surface of color coated aluminum coils. Successful solution of the problem would help to reduce …

Nydia

Nydia

Sales Manager

Sales Manager