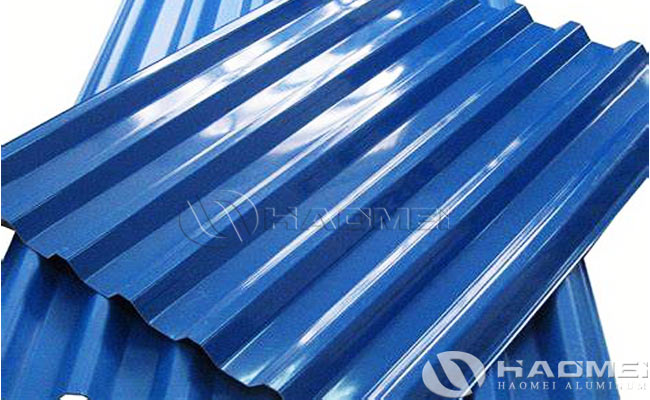

Powder Coated Aluminium Roofing Sheets

August 15, 2025

Powder coated aluminum roofing sheets are a building material made from high-quality aluminum alloys, treated with a powder coating process. They are widely used in roofing systems for commercial buildings, industrial plants, and residential buildings, offering excellent performance and a beautiful appearance.

Specifications of powder coated roofing sheets:

– Material: High-quality aluminum alloy (such as 3003, 3004, 3104, 3105, 5052, 6061, etc.)

– Thickness: Typically between 0.5mm and 2.0mm, customizable upon request

– Coating thickness: Typically between 50μm and 100μm

– Color: Customizable to meet customer needs, with RAL color palette options available

Features of powder coated aluminum roofing sheets:

– Excellent decorative properties:

Powder coatings can be formulated in a wide variety of colors, including solid, metallic, matte, and high-gloss finishes. They can also create unique textures, such as wood and stone grain, to suit diverse architectural styles and design requirements, providing roofs with a unique and aesthetically pleasing appearance.

– Excellent Weather Resistance:

It offers excellent UV resistance and resists fading and chalking under prolonged sunlight. It also resists erosion from natural environmental factors such as acid rain, salt spray, and sandstorms, maintaining stable performance under varying climate conditions and extending the lifespan of the roof.

– High Corrosion Resistance:

The coating effectively isolates the aluminum roofing sheet from moisture, oxygen, acids, and alkalis in the external environment, preventing corrosion. Even in coastal areas or environments with heavy industrial pollution, it effectively protects the aluminum sheet from corrosion damage.

– Strong Mechanical Properties:

The powder-coated coating offers high hardness and adhesion, is abrasion-resistant and impact-resistant, and is resistant to scratches and damage. During roof installation and use, it can withstand certain external forces, such as collisions and friction caused by pedestrians and equipment installation.

– Environmentally friendly and energy-saving:

Powder coating contains no organic solvents and releases no volatile organic compounds (VOCs) during the spraying process, making it harmless to the environment and human health. Furthermore, aluminum panels inherently have excellent thermal insulation properties. Combined with a powder spray coating, this further enhances the roof’s thermal insulation and reduces the building’s energy consumption.

– Economical and practical:

The powder spraying process is relatively simple, highly efficient, and can be automated, reducing labor costs. Furthermore, the coating offers excellent durability and low maintenance, reducing the frequency of subsequent roof renovations and repairs, resulting in high overall economic benefits.

Manufacturing process of powder coated aluminum roofing sheets:

- Surface Pretreatment:

The aluminum sheets are cleaned to remove impurities such as oil, dust, and scale. Degreasing and chroming are then performed to improve surface adhesion and corrosion resistance, preparing the aluminum sheets for subsequent powder coating.

- Powder Coating:

Using electrostatic spray equipment, dry powder coating is evenly applied to the pretreated aluminum sheets. The static electricity attracts the powder to the aluminum sheets, forming a uniform powder coating.

- High-Temperature Curing:

The powder coated aluminum sheet is placed in a high-temperature oven for baking, allowing the powder coating to melt, level, and solidify at high temperatures, forming a durable coating. Curing temperature and time vary depending on the type of powder coating, the material and thickness of the aluminum sheet, and are generally adjusted between 180°C and 200°C for 10-20 minutes.

Applications of powder coated roofing sheets:

– Industrial Buildings:

For roofs of factories, warehouses, and other structures, powder-coated aluminum roofing provides excellent waterproofing, corrosion resistance, and thermal insulation, meeting the requirements of industrial production.

– Commercial Buildings:

Powder-coated aluminum roofing is often used on the roofs of commercial buildings such as shopping malls, hotels, and office buildings to create an aesthetically pleasing and durable exterior while improving overall building quality and energy efficiency.

– Public Buildings:

Airport terminals, train stations, stadiums, exhibition halls, schools, hospitals, and other public buildings require high roof performance and aesthetics. Powder-coated aluminum roofing sheets can meet these building needs in terms of both functionality and appearance, showcasing a unique architectural style.

– Residential Buildings:

Powder-coated aluminum roofing sheets have also found application in some high-end residential communities, villas, and other residential buildings, providing an aesthetically pleasing and durable roofing solution while enhancing the overall value of the residence.

Due to its superior performance and aesthetic appearance, powder coated aluminum roofing sheets have become an indispensable material in modern architecture, suitable for a variety of roofing solutions.

Nydia

Nydia

Sales Manager

Sales Manager