PVDF wood grain aluminum coil for furniture

The employment of pvdf aluminum coil in furniture is not novel any more. The patterns of the coil fall on two types: wood grain pattern and pure color pattern. The former includes patterns of white oaks, golden oaks, rosewoods, red teaks etc., and the latter covers not only traditional pure colors but aggressive modern colors like bright yellow and light …

Black aluminum coil 1100 3003 3004 4105 5005 5052

Black aluminum coil is a color coated aluminum coil from 0.25mm to 4.0mm thick, used in building, decoration, electronic products, home appliances, traffic equipment, automobile, furniture etc. Haomei supplies black aluminium coil of specifications as below. Alloy: AL1100, AL3003, AL3004, AL3105, AL5005, AL5052 Coating: fluorocarbon coating, polyester coating Thickness: 0.25mm-4.00mm Processing width: color coated aluminum coil 150mm-1500mm; color coated aluminum …

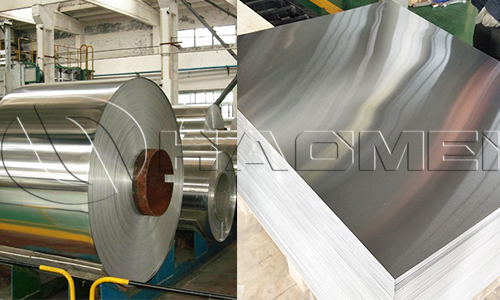

3003 2a12 1050 1060 5083 5052 6061 7075 aluminum alloy

3003 2a12 1050 1060 5083 5052 6061 7075 aluminum coil and sheet aluminium coil or strip covers 1xxx, 3xxx, 5xxx, 6xxx and 7xxx series and their all possible shapes. Here we deal with only the representative alloy of each series. 1050 aluminum coil is the representative of 1xxx series. In addition to the coil type, 1050 can also be made …

Differences between pure and alloy aluminum coil

A pure aluminium coil refers to 1xxx series of aluminium coil, like the 1070 aluminum coil for sale, while an alloy alu coil stands for alu coil rolls of all other series, including 3xxx, 2xxx, 4xxx, 5xxx, 6xxx, 7xxx and 8xxx, among which only 3 are the most frequently applied. 1xxx coil is known as the pure coil group because …

Top quality 3003 aluminum coil for letter

3003 aluminum coil for letter is a painted or anodized aluminium product with an alloy metal of manganese alloy. 3003 is the most widely used of all alloys. It is basically a commercial pure aluminium and is 20% stronger than 1100. It has good hardness, corrosion resistance but relatively poor anodizing property. Anodized 3003 aluminum sheets or rolls might have …

Is 3003 aluminum coil used for beverage cans

3003 aluminum coil ranks top in popularity among Al-Mn aluminium sheet rolls which serve as an excellent material for beverage cans. 3003 used to be used in beverage cans. Due to the manganese alloy element, it shows excellent anti-rust properties. Aluminum will form an oxide film on the outside in the air, namely aluminum oxide, which prevents aluminum from being …

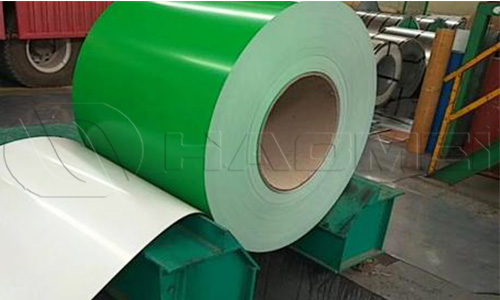

Aluminum coil for alu composite panel

Aluminum coil for alu composite panel can be of 1xxx, 3xxx and 5xxx series. After being treated by coating or anodizing process, it combines plastic materials to form panels for construction and decoration. This combination of two materials (metal and non-metal) not only retains the main characteristics of the original constituent materials (metal aluminum, non-metal polyethylene plastic), but also overcomes …

Pvdf coat wood grain aluminum coil for wall cladding

PVDF coat aluminum coil of wood grain for wall cladding can be more expensive than regular aluminum coil rolls, because both the adoption of the PVDF paint and the wood grain pattern coating process entail extra cost. Haomei supplies wood grain pvdf coat aluminum coil of the following specifications: Inner core: 405mm and 505mm inner diameter horizontal packaging Protective film: …

Aluminum coil pre painted with pvdf coating

Aluminum coil pre painted with pvdf coating find its applications in roofing, ceiling, flooring, wall cladding and various other decorative purposes. Its alloys cover 1xxx, 3xxx and 5xxx series. 1xxx here mainly refers to 1100 and 1050. They have the lowest strength and weakest corrosion resistance as a mill finish material. 3xxx includes 3003, 3004, 3005 and 3105, featured by …

Things you need to know about wood grain aluminum coil

Differences from pure color coated aluminum coils The surface treatment methods of wood grain aluminum coils include: laminating, painting, baking and rolling. The surface treatment method of ordinary color coated aluminum coil does not include laminating. The process is divided into surface treatment, roll coating and curing. How to choose wood grain aluminum coils for sale Treatment method is a …

1050 aluminum painted coil for roof and wall decoration

1050 aluminum painted coil is a regular material for buildings in roofing, ceiling and wall decoration. 1050 is the most popular alloy of 1000 series, containing 99.5% aluminium metal. It’s only a little weaker than 1100 and share similar mechanical properties: low strength, good corrosion resistance and cheap price. Owing to the fact that it only differs slightly from 1060 …

Processes to keep aluminum coil rolls from being corroded

Some processes help to keep a roll of aluminum coil from being corroded, including color coating, anodizing, filming etc. Although pure aluminium and aluminium alloy coils are naturally corrosion resistant, their properties are not strong enough in some application cases like roofing, ceiling and insulation that requiring higher resistance to water, sunshine, high temperatures etc. Color coating is the most …

Nydia

Nydia

Sales Manager

Sales Manager