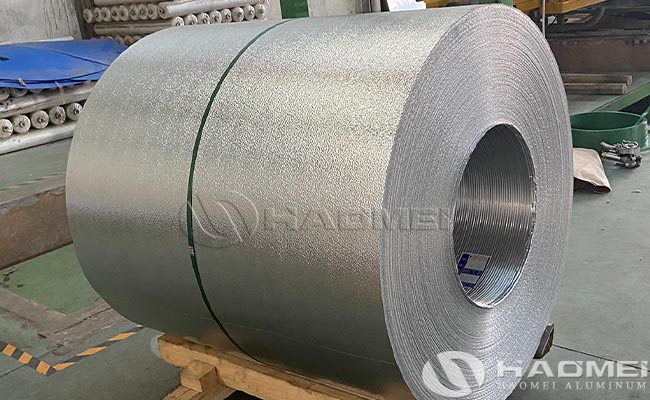

Orange Peel Stucco Embossed Aluminum Coil

June 16, 2025

The surface of the orange peel stucco embossed aluminum coil presents a pattern similar to that of orange peel, with clear lines and a strong three-dimensional sense. There are different patterns such as classic orange peel and variant orange peel, which can add a unique decorative effect to the embossed aluminum coil product.

- 1. Appearance characteristicsof orange peel aluminum coil:

– Texture: The surface presents an uneven texture similar to that of orange peel (also known as worm pattern), which is pressed by an embossing machine, and the pattern is beautiful and generous.

– Color: The basic material is silver-white, and a variety of colors (such as color, matte, mirror, etc.) can be achieved through coating processes (such as polyester, PVDF).

– Gloss: The surface is smooth or slightly frosted, depending on the coating process.

- 2. Specificationsof orange peel stucco aluminum coil:

– Thickness:

Common thickness range: 0.3mm to 1.0mm (such as 0.3mm, 0.4mm, 0.5mm, 0.6mm, etc.).

Some special needs can be customized with thicker or thinner specifications (such as 0.15mm or 3.0mm).

– Width:

Conventional width: 800mm to 1550mm (some suppliers can provide 1220mm, 1250mm, etc.).

Can be cut into small rolls (such as 50 meters/roll) or large rolls (2.5-3 tons/roll).

– Material:

Common alloys: 1060 (pure aluminum), 3003 (rust-proof aluminum), 5052 (corrosion-resistant aluminum), etc.

- 3. Core featuresof orange peel embossed aluminum coil

– Lightweight and high strength:

Aluminum has a low density (2.71g/cm³) and weighs only 1/3 of steel, which reduces the structural load.

– Corrosion resistance:

Aluminum alloy natural oxide film + coating process, excellent weather resistance, service life of 20-30 years (such as salt spray test 2000 hours).

– Easy to process:

Can be bent, stretched, welded, adapt to complex modeling requirements, high construction efficiency.

– Anti-slip and wear-resistant:

The surface texture design reduces light pollution and enhances friction, suitable for anti-slip scenes (such as floors, carriages).

– Environmentally friendly and economical:

High recyclability (recycling value is several times that of iron sheets), in line with green building and circular economy requirements.

– Customization:

Supports customization of size, color, coating (such as fluorocarbon, polyester) and pattern (classic orange peel/variant orange peel).

- 4. Application areasof orange peel stucco embossed aluminum coil:

– Industrial insulation:

Pipeline insulation (such as chemical plants, power plant equipment), cold storage, refrigerator refrigeration systems, etc.

– Architectural decoration:

Curtain walls, interior decoration, cabinets, ceilings, etc., both beautiful and functional.

– Home appliance manufacturing:

Home appliance housings (such as air conditioners, refrigerators), electrical accessories (such as radiator housings).

– Transportation facilities:

Automobile exhaust pipes, rail transit interiors, lightweight structural parts.

– New energy:

Photovoltaic power station frames, energy storage battery boxes, hydrogen energy storage bottle liners.

Nydia

Nydia

Sales Manager

Sales Manager