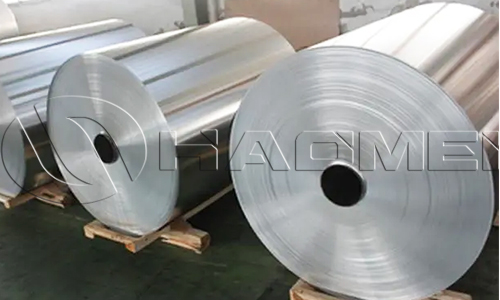

Coil Aluminum For Sale

Coil aluminum for sale on the market are usually classified into several series according to their alloy compositions, which include 1000 series, 3000 series, 5000 series and 6000 series. Below is a brief description of each series of coil aluminum for sale: 1000 Series Aluminum Coil – The main component is aluminum content of more than 99%, belonging to the pure aluminum …

Aluminum Coil Manufacturers In China

Aluminum coil manufacturers in china have advanced production equipment, complete product specifications, good product quality and wide application scope. Haomei Aluminum is a member of the top aluminum coil manufacturers in China, with more than 20 years in the aluminum processing industry, Haomei have been a reliable aluminum product manufacturer. China aluminum coil manufacturers are usually equipped with advanced aluminum coil production …

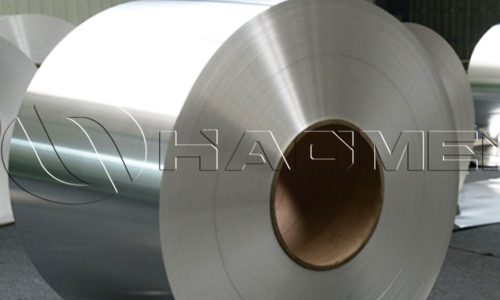

Bright Aluminum Coil

Bright aluminum coil (also known as glossy aluminum coil or mirror aluminum coil) is an aluminum alloy material with a special surface treatment that provides a smooth, bright surface. It is commonly used in a variety of industrial and architectural applications. Specification of bright aluminum coil: – Thickness: Bright aluminum Coil is available in a wide range of thicknesses, with common …

Aluminum Sheet Metal Coil

Before the aluminum sheet metal coil is rolled, some pretreatment sections are required to ensure that the surface of the aluminum coil is clean. Avoid the residual grease and smoothing agent on the surface, which will affect the coating and application. Therefore, the aluminum sheet coil must be pre-treated in the following aspects before it is formed. First, use hot …

Aluminum coil sheet 5052 for beverage cans

Aluminum coil sheet 5052 has many applications, and beverage cans are one of them. Standards for beverage can materials are very strict. They should be light, strong and portable. The application of aluminium in beverage cans dates back to the 1960s in America, when the unit weight of cans was about 60g, much lighter than that of other materials already. …

5052 h32 aluminum coil for sale

5052 h32 aluminum coil has stabler mechanical properties than 5052 H22 alu coil. It’s been work hardened and then stabilized to 25% of the full hardness. Therefore, it’s only a little harder than 5052 O aluminium. 5052 boasts good fatigue strength, high elongation and strong corrosion resistance itself. Its coil of H32 state displays such features excellently. The coil can …

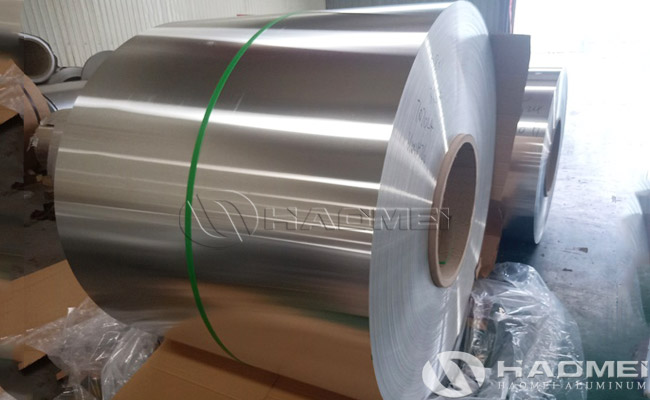

Mill finish aluminum coil

Mill finish aluminum coil is the basic state of aluminum coil, namely, the initial state of aluminum coil without any subsequent processing. Its production process includes melting and casting, homogenization, hot rolling, cold rolling, annealing, leveling, shearing and inspection. In the melting and casting process, it is necessary to configure the required alloy composition first, then the material is treated …

Gold coat aluminum coil specification and price

A gold coat aluminum coil is also known as gold aluminum coil, obtained by the process of color coating or anodizing. The thickness is usually between 0.1mm and 3mm thick, mostly around 1mm thick in practice. The width is up to 1600mm, and minimum width can be customized, for even strips are available for decoration and channel letters. The width …

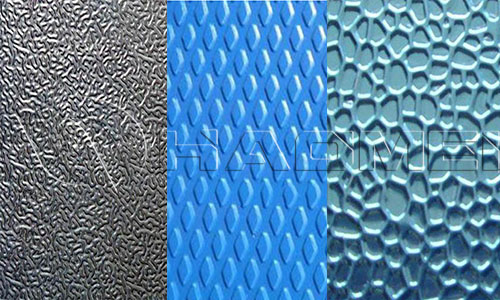

1xxx series emboss aluminum coil for roofing and insulation

1xxx series emboss aluminum coil for roofing and insulation include grades of 1050, 1060 and 1100. Embossed roofing coil is usually painted, and insulation coil is of diamond or stucco pattern. Roofing aluminum coil is usually painted at last, the surface can be first mill finished or embossed. An emboss aluminum roof coil can be of 1xxx or 3xxx series, …

Pattern aluminum emboss plate coil used for building

A pattern aluminum emboss plate coil is used for building in wall cladding, stair treads, room partition surface panels etc. Thickness is from 0.01mm to 3.0mm. Embossed aluminum coils are aluminum products with various textures on the surface after calendering. They have very good anti-slip and decorative effects. Typical end products are anti-slip flooring, anti-slip step ladders, packaging and engineering …

Aluminum color coil types and prices

Aluminum color coil falls on three types by processing methods: color coated aluminium coil, mirror finish anodized aluminum coil and brushed anodised aluminium coil. Color coated aluminum coil is the most popular type in either production or application. When we speak of aluminum color coil, we refer to aluminum coil with paint coating if there are no special notes. This …

3105 china pp cap aluminium coil suppliers

Among leading 3105 china pp cap aluminium coil suppliers, Haomei 3105 pp cap aluminum coil has been winning great popularity in both domestic and global markets. 3105 aluminum bottle cap materials are widely used in food packaging. Because aluminum has good oxidation resistance, a dense oxide film is formed on the surface of aluminum, which protects the original physical properties …

Nydia

Nydia

Sales Manager

Sales Manager