PVDF Powder Coated Aluminum Sheet Metal

July 7, 2025

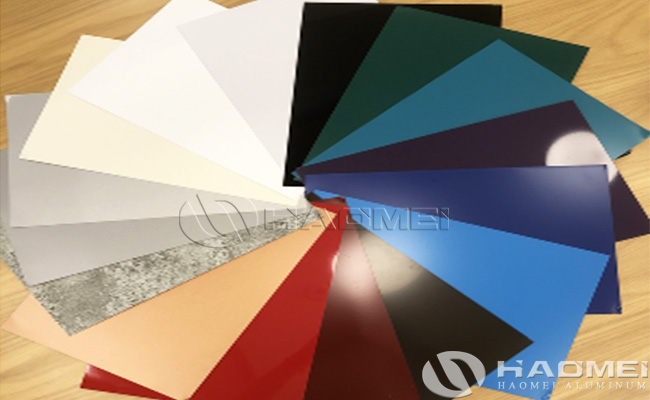

PVDF powder coated aluminum sheet is a coating formed by evenly spraying high-performance PVDF resin powder on the surface of the aluminum sheet and curing it at high temperature. This coating not only has excellent adhesion, but also provides excellent weather resistance, corrosion resistance and UV resistance. The PVDF coating has rich colors and high gloss, which can meet the needs of different architectural styles.

Advantages of PVDF powder-coated aluminium sheet

– Excellent weather resistance:

PVDF coating can withstand various harsh weather conditions, such as strong sunlight, heavy rain and high temperature. Its weather resistance makes the aluminum sheet not easy to fade during long-term use, maintaining its beautiful appearance.

– Excellent corrosion resistance:

PVDF material has extremely strong chemical stability and can resist erosion by acids, alkalis and other chemicals. This makes PVDF powder-coated aluminum sheet very suitable for marine environments, industrial areas and other places with strong corrosiveness.

– Excellent aesthetics:

PVDF powder-coated aluminum sheet has a smooth surface and rich colors, which can meet the designer’s high requirements for the appearance of the building. Through different spraying processes, a variety of visual effects can be achieved to enhance the overall beauty of the building.

– Environmental protection:

PVDF powder spraying technology meets environmental protection standards, the coating does not contain harmful substances, and less waste gas and wastewater are generated during the production process, which is in line with the concept of sustainable development.

– Reduce maintenance costs:

Due to the durability and self-cleaning properties of PVDF coating, aluminum plates are not easy to accumulate dust and dirt during use, reducing the frequency of cleaning and maintenance, thereby reducing long-term maintenance costs.

As a professional PVDF coated aluminum coil supplier, Haomei Aluminum has significant competitive advantages in the production of PVDF powder sprayed aluminum plates.

– Advanced production equipment:

We have introduced internationally leading spraying equipment and technology to ensure that each aluminum plate can achieve high standards of coating quality. Our equipment can achieve precise spraying process, ensure uniform coating thickness and strong adhesion.

– Strict quality control:

Haomei Aluminum implements a strict quality management system in the production process, and every link from raw material procurement to production process is strictly controlled to ensure the high quality of the product. We conduct product testing regularly to ensure that each batch of goods meets international standards.

– Strong R&D capabilities:

We have a professional R&D team dedicated to the development of new materials and new processes. According to market demand, new PVDF powder-coated aluminum sheets are regularly launched to meet the diverse needs of customers.

– High-quality after-sales service:

We always put customer needs first and provide all-round support from pre-consultation to after-sales service. Our professional team will provide technical guidance to customers to ensure that customers have no worries during use.

Flexible customization capabilities: Haomei Aluminum can provide PVDF powder-coated aluminum sheets of different specifications, colors and coating thicknesses according to customers’ specific requirements to meet the needs of various construction and decoration projects.

PVDF powder-coated aluminum sheets have become an important choice for modern architectural decoration due to their excellent performance and beautiful appearance. As an industry-leading aluminum supplier, Haomei Aluminum is committed to providing customers with the highest quality products and solutions with advanced technology, strict quality control and high-quality services. We look forward to working with you to jointly promote the sustainable development of the construction industry.

Nydia

Nydia

Sales Manager

Sales Manager