Champagne Anodized Aluminum Sheet

Champagne anodized aluminum sheet is an aluminum alloy sheet that has been anodized, resulting in a champagne gold luster. This anodized aluminum sheet not only offers a beautiful decorative effect but also boasts excellent corrosion and wear resistance. Its antioxidant and decorative properties make it widely used in architectural curtain walls, furniture, interior decoration, and electronic products. The anodizing process increases the …

Anodized Sheet

Anodized sheet is to make the aluminum plate undergo relative treatment to form a layer of oxide film on the surface, which is called anodized aluminum sheet. According to different processing technology, anodized aluminum plate is also divided into anodized aluminum plate and organic chemical alumina plate. The anodized aluminum plate is to place the aluminum plate in the relative lithium battery …

Color Anodized Aluminum Sheet

The surface treatment technology of the color anodized aluminum sheet is different from the ordinary painting technology. It electrolyzes the conductive acidic electrolyte through the electric current, so that the aluminum sheet metal surface that constitutes the anode is oxidized, and a thick and fine layer of aluminum oxide film protection naturally grows on the aluminum surface, this oxide film is …

Anodized Aluminum Sheet Metal Factory

The anodized aluminum sheet metal factory offer product durable and can be dyed into colorful colors, which is pleasing to the eye. Anodizing and dyeing is a very widely used decoration technology in aluminum sheet metal surface treatment. This technology can not only improve the corrosion resistance and light resistance of aluminum and aluminum alloy sheet metal products, but also it …

How to avoid color difference of anodized alu sheets

Whatever you are a producer or buyer, here are tips for avoid supplying or buying anodized aluminum sheets with color difference. Reasons for color difference of anodized aluminium sheets: A. Variation in the solution composition, content, concentration, temperature, treatment time and other factors; B. Color difference in the original base sheets, in which case color difference will still occur even …

Can 7xxx aluminum sheet be anodized

7xxx aluminum sheet, an aluminium zinc magnesium alloy, contains alloys of 7075, 7050 and 7005 etc. As known to all, 5xxx aluminium sheets boast excellent anodizing effect, especially suitable as housing materials for electronic products. Can 7xxx aluminium plates be anodized, too? The answer is positive. Known as an aircraft aluminum sheet, 7xxx plates are light in weight and strong …

Possible disadvantages of anodized aluminum sheet

Anodized aluminum sheets are more frequently mentioned with its advantages, and it looks as if there are no disadvantages at all. Yet this is not always the case. Failures in any step of anodising process might lead to the following weaknesses of a pre anodized aluminum sheet. The first is transparency reduction. Aluminium sheets have their own transparency. The process …

Bronze anodized aluminum sheet used in building

Bronze anodized aluminum sheet has a hard adhesive film with outstanding hardness and wear resistance. With a solemn color similar to traditional wooden furniture, the sheet serves as a novel material in exterior and interior decoration of buildings. Anodizing technology overcomes the defects of traditional aluminum alloy surface treatment technology in terms of hardness and wear resistance, and also overcomes …

Can 3003 aluminum sheet be anodized

Can 3003 aluminum sheet be anodized? It’s said that 3003 aluminium is seldom anodized, for the sheet color is not even after being anodized. If you probe further, however, people are anodizing 3003 alloy sheets as a matter of fact. 3003 has manganese as its alloy metal, displaying excellent forming ability, high corrosion resistance, good welding property and outstanding electricity …

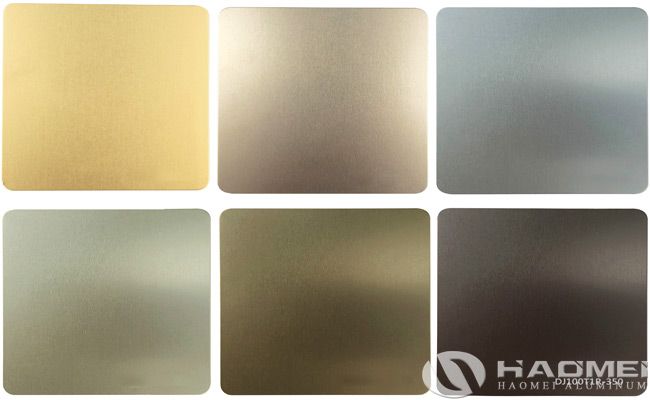

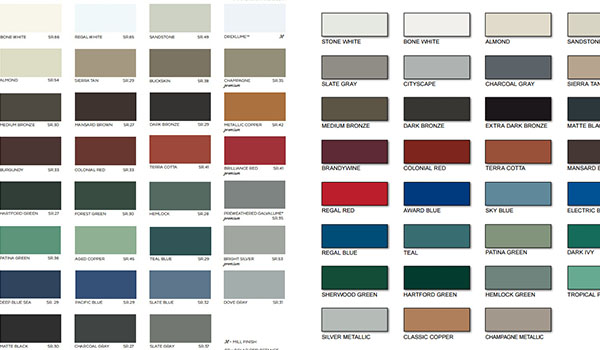

Anodized aluminum sheet pantone

Anodized aluminum sheet pantone varies from supplier to supplier, but mostly consists of several color series: gray (including silver), red, blue, green, brown, red. Theoretically anodized aluminium sheets of each existing color can be made, which entails adjusting in coating process. The color of aluminum sheets by primary anodizing silver (the same as aluminum itself), and color anodizing is realized …

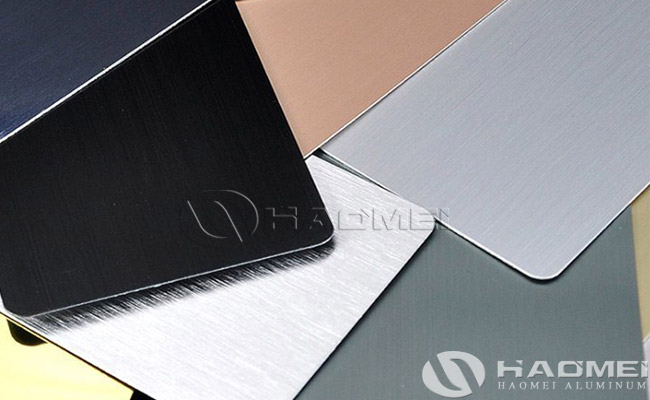

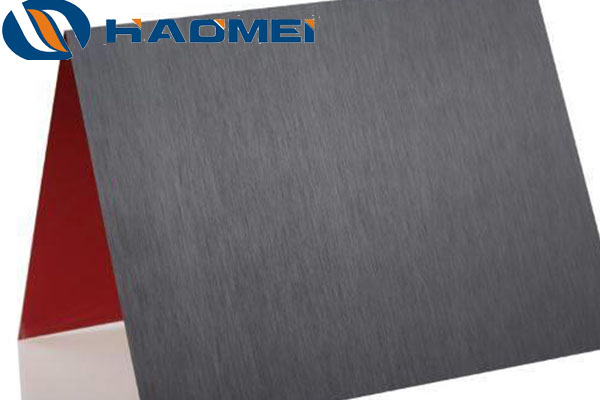

Anodized brushed aluminum sheet

An anodized brushed aluminum sheet can be of alloys covering 1xxx to 7xxx series, including 1060, 1100, 1050, 1070, 2A12, 3003, 3004, 5052, 5A02, 5083, 5754, 6061, 6063, 6082 and 7075. Regular tempers include soft state(O, H111), hard state (H18, T6) and medium hard state (H24, H22, H32 and H112) to cater for requirements of varied clients. The sheet is …

Black anodized aluminum sheets

Black anodized aluminum sheets are obtained by anodizing and coloring the surface of targeted aluminium sheets. Anodizing is a material protection technology for an aluminum plate to form oxide film on its surface by applying anode current in electrolyte solution. Cast aluminum can be black by common anodizing. After anodizing, the sheet is dyed with a black solution: acid MaoYuan …

Nydia

Nydia

Sales Manager

Sales Manager