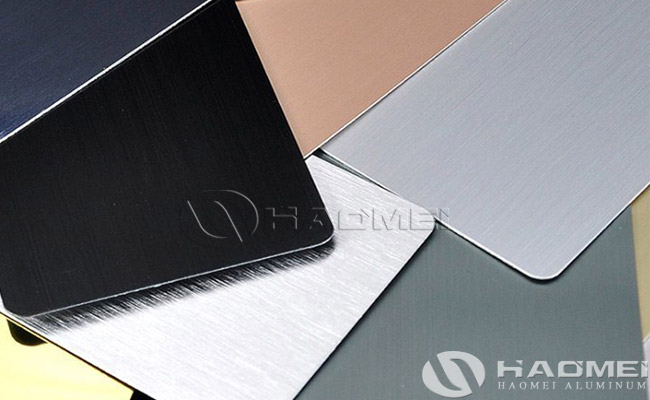

Anodized Sheet

March 20, 2023

Anodized sheet is to make the aluminum plate undergo relative treatment to form a layer of oxide film on the surface, which is called anodized aluminum sheet. According to different processing technology, anodized aluminum plate is also divided into anodized aluminum plate and organic chemical alumina plate. The anodized aluminum plate is to place the aluminum plate in the relative lithium battery electrolyte (such as hydrochloric acid, chromic acid, hydrochloric acid, etc.) for anodic oxidation, and carry out electrolysis under special conditions and the effect of additional current. The anodized aluminum plate is oxidized, and the aluminum oxide layer is formed on the surface. The thickness is 5-20 μm, and the hard anodized film reaches 60-200 μm.

Anodized sheet is aluminum plate in weak alkaline or acidic aqueous solution, part of the base metal material reacts, making the natural oxide film on the surface thicker or forming other passivation treatment film Treatment methods, common organic chemical oxide films include chromic acid film and ammonium sulfate film, which are both thin and good in adsorption, and can be treated by coloring and grouting reinforcement. The aluminum alloys of anodized aluminum sheet are 5052, 6061, 6063, 6082, 7075 and so on, they have different performance and also have different application field.

Anodic oxidation and organic chemical oxidation are different in processing technology, resulting in different oxide film characteristics. Compared with aluminum anodic oxidation film, organic chemical oxide film is much thinner, with lower corrosion resistance and strength. And it is not easy to color, and the light resistance after coloring is poor, so the color and color of the aluminum plate only introduces the anodizing treatment.

Nydia

Nydia

Sales Manager

Sales Manager