Specifications and price of bottle cap aluminum coil

July 23, 2020

An aluminum trim cap coil merges as a new bottle cap sealing material with characteristics of beautiful appearance, good sealing effect and satisfying counterfeit function. As a result, it catches on in the sealing packaging of beverage bottles, wine bottles, cosmetic bottles, medicine bottles at home and abroad.

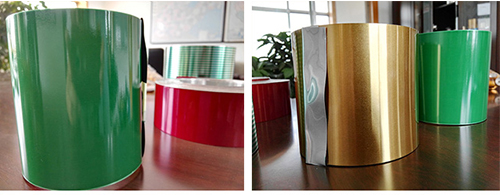

Specifications of bottle cap aluminium coil are as below. Its alloys cover 1060, 3003, 1100, 3104, 5052 and 8011. They share attributes of light weight, excellent deep drawing property, low ear rate and strong adaptability to printing methods. Among them 5052 proves to be the strongest and most corrosion resistant, suitable for higher requirements in bottle sealing. Thickness of the coil ranges between 0.012mm and 0.5mm, for 3003 and 8011 can be made into foil type as a bottle capping material. The width begins with 100mm and ends at 1600mm. Sometimes the coil roll is cut into sheets as required by some clients, and the length can be customized. Although there are no words like “color coating” in the name, an aluminum bottle cap coil is actually an aluminum trim coil, namely, color coated aluminum coil, for most clients ask to film the surface and print logos on it with a purpose to save further processing steps. When they receive the rolls, they punch them directly into caps of various sizes.

Price for pp cap aluminum coil materials varies from specification to specification. Available aluminum coil stocks for pp caps cover 1, 3, 5 and 8 series. The equipping of a precision integrated plate profile control system greatly improves our product quality. The aluminum coils we produce for bottle caps is smooth and free of defects such as cracks, bubbles, penetrating pores, pressing marks, and stripes. In addition, we implement a strict quality management system. Width and thickness tolerances are implemented according to the requirements of the process card. In the coil rolling process, the surface quality is checked one time with at least every 3 coils, and the surface quality is checked for each coil of the finished product pass. In the production of bottle cap aluminium sheets, the quality of the slices is strictly monitored to ensure that there are no burrs, knife back marks or lotus leaves. If you want to learn about prices of Haomei aluminium coil for pp caps, welcome to contact us at april@aluminumhm.com or send messages at “contact” on the upper right of the page!

Nydia

Nydia

Sales Manager

Sales Manager