Aluminum trim cap coil quality control

July 1, 2020

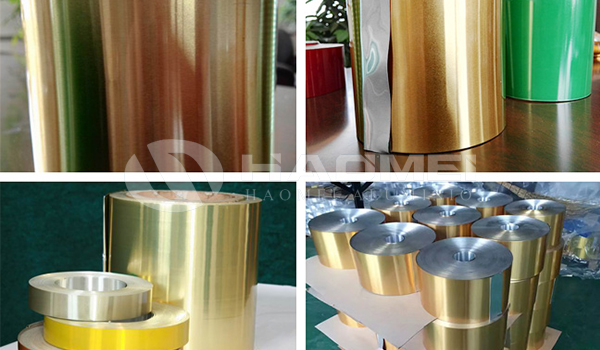

Haomei realizes quality control of its aluminum trim cap coil through aluminium stocks, process, stretch bending and instant quality inspection.

The stocks for aluminum cap coil must have a medium crown of 0.2-0.8% and longitudinal thickness difference not more than 0.1M. The surface of the blanks should be free from cracks, bubbles, pores, corrosion, peeling, periodic marks, metal and non-metal pressing marks, aluminum sticking, light and dark stripes or other defects.

In the rolling process the blank surface, the roller surface should be cleaned thoroughly and the inferior ends of the blanks must be cut off first. The lubricant temperature should be kept between 35 ~ 50c, the working pressure above 0.55mpa, and the oil transmittance more than 90%. The position of splash proof plate should be adjusted strictly to ensure the effect of oil removal by wind blowing so that no oil will be left on the strip or coil surface.

The roughness of the finished rollers should be between 0.35-0.4um and the thickness error within ±0.005mm. The rolled aluminum coil strip must be even in edge without sharp bumps and the coil strip surface must be free from indentation, marks, oil stains, black lines, bright lines, roll marks, cross layer and other defects. These standards are carried out by random inspection of at least every 3 rolls. In addition, samples will be fetched from finished rolled aluminium coil (transverse, longitudinal and 45 degree directions) and sent to the laboratory center for inspection of tensile strength, yield strength, elongation and ear making rate.

In the stretch bending process, the contact guide rollers of tension roller and squeezing roller must be cleaned thoroughly by clean water. The uncoiling tension should be less than the coiling tension of the previous process. The coiling and backing should be flat without deflection and sharp bulge.

Finished aluminum trim coil for caps should meet the following requirements. First, the width and thickness tolerance shall be implemented according to the requirements of process card. Second, the surface of the aluminum trim cap coil should has no scratches, marks, oil stains, black wires, bright lines or roller marks. Third, the edge cutting should be free from burrs, knife back marks and lotus leaf edges.

Haomei aluminum trim cap coil rolls meet various further process requirements, suitable for colored printing and deep drawing. We guarantee that the shape of the rolls is flat, the geometric dimension accurate, the surface gloss high, and the alkaline washing effect good, which can reach the level a of water brushing experiment. The end face of aluminum strip is flat without parabola, collapse and other defects. Welcome to contact us at april@aluminumhm.com for more information!

Nydia

Nydia

Sales Manager

Sales Manager