Features of Mirror Finish Anodized Aluminum Sheet for COB

November 29, 2018

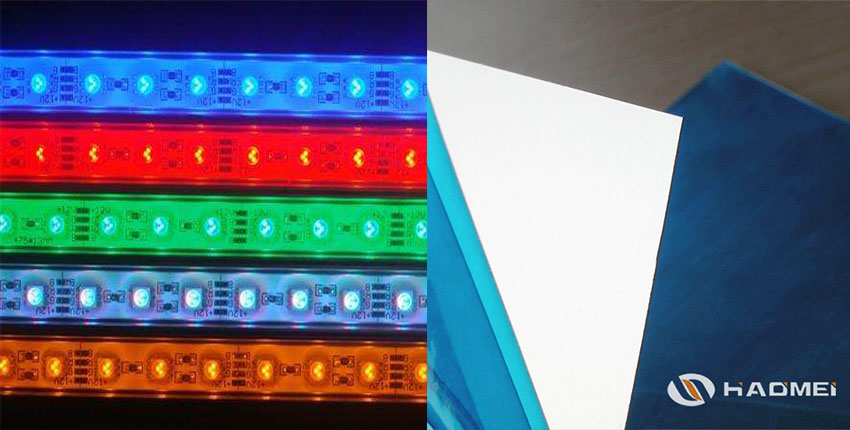

An aluminum substrate serves as one of the most important component for LED lamps. The most suitable aluminum product for the substrate proves to be mirror finish anodized aluminum sheet, which is featured by good heat exchange, high reflectivity, convenient operation and low cost.

The technology of electrically neutral thermal path is applied to the substrate of mirror anodized aluminum sheet whose heat conductivity is 137W, much higher than that of common aluminum substrates (1W, 1.5W, 2W) and greatly enhancing the heat exchange rate of the chip. The reflectivity of regular nickel aluminium substrates is 80%, cup hole aluminium substrate 85%, silver alu substrate 95 and silver aluminum mirror sheet 98%. Mirror finish anodized aluminum sheet is able to bring the best of the chip light. Its substrate has a structure similar to that of an integrated holder whose wires are connected to each other, and the connecting methods or electricity power can be decided by individual customers later. Different from common welding discs holding a given number of chips, aluminum mirror sheet substrates can hold several lamps at the same time, which efficiently solves the problem of stored substrates of varied models. In addition, the chips can be installed densely and directly on the surface of the substrate, which spares followed processing steps and eventually reduces production cost.

Haomei supplies mirror finish anodized aluminum sheet of 1050,1060, 1070, 1100, 3003, 5005 and 5057. The thickness available ranges from 0.2mm to 4.5mm. We have established long term business relationship with clients from over thirty countries. Our mirror finish aluminum sheets are made into lamp parts and decorative components in various places of the world.

Nydia

Nydia

Sales Manager

Sales Manager