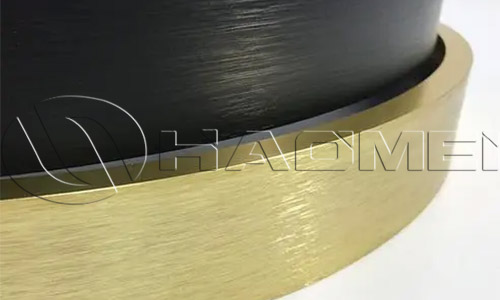

Brushed aluminum trim strips for sale

May 20, 2021

Brushed aluminum trim strips are mainly applied to decorative conditions like interior and exterior decoration. They can be made of 1000, 3000 and 5000 series, depending on the properties you need. Relative alloys incorporate 1050, 1060, 1070, 1100, 3003, 3004 and 5052. The strips, processing by the method of brushing and color coating, display regular lines on the surface. People tend to assume raw aluminum rolls should be brushed first and then color coated, yet the practice goes just the opposite. The narrow rolls get colored before being brushed. To do this the thickness and adhesion of the coating layer must be big and strong enough, or else the layer would be damaged or peel off during the brushing period.

Alloys of the strips above stand for varied performances in hardness, forming ability, tensile strength and corrosion resistance. 1050, 1060, 1070 and 1100 are the softest, most easy to be formed, and most vulnerable to erosion. 3003 and 3004 is better in anti-rust ability, but poorer in tensile strength. 5052 is the strongest in both rust resistance and hardness, while it’s elongation proves to be the smallest. Thus you need to choose based on your practical needs. If want to combine several factors, however, there’s still one way to achieve this: temper. Tempers of these alloys cover O, H12, H14, H16, H18, H22, H24, H26, H32, H34 etc. If you need soft 5052 brushed aluminum strips, O state would be the best choice. If you need very hard 1100 brushed aluminum trim strips, you can choose H18 state, the hardest state of any alloy.

Haomei supplies brushed aluminum trim strips of 0.02mm-4.0mm and width up to 1200mm. They are applied to furniture, blinds, windows, doors, ceiling, cupboard, channel letters, lighting decoration etc. As a result, our clients for the strips alone come from various industries from tens of countries.

Nydia

Nydia

Sales Manager

Sales Manager