Stucco Embossed Aluminum Sheet VS Iron as Fridge Evaporators

December 5, 2018

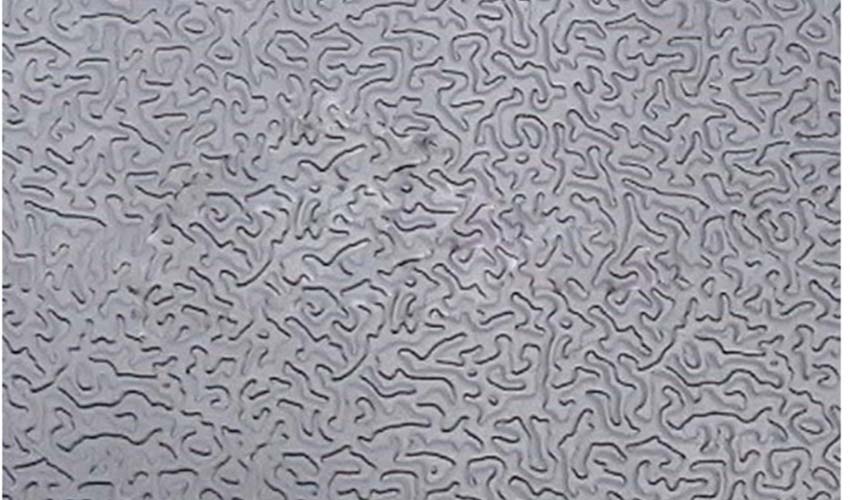

Owing to their strict requirement about heat conductivity, fridge evaporators are usually made of metals. The iron sheet and the stucco embossed aluminum sheet serve as two regular candidate materials. In comparison to iron, stucco aluminum sheet is a relatively new material for fridge evaporators, and some people have doubts about its safety as well as properties. Here let’s make a detailed comparison between iron and embossed aluminum in bearing capacity, corrosion resistance, cooling speed and material cost.

The cooling room panel has a full contact with evaporator made of stucco embossed aluminum sheet. The evaporator covers such a large and even cooling area that its bearing capacity reaches as much as 30kg. Iron evaporators are featured by more welding points, the paints of which get peeled from frequent rubbing against the cooling drawer. As a result, paint particles falls into stored food and exposed iron gets rusty quickly. The whole fridge stops working once the welding points fall apart. The heat conductivity of aluminium is 237w/mk and iron 80w/mk, which means stucco embossed aluminum sheets have a much better heat conductivity. A fridge with an aluminium evaporator has a cooling speed three times of that with an iron evaporator. As for material cost, alu embossed sheets costs four times more than iron sheets. Therefore, some fridge manufacturers still adopt iron evaporators in order to save cost.

Nydia

Nydia

Sales Manager

Sales Manager