Polishing methods for polish mirror aluminum sheets

March 5, 2020

A polish mirror aluminum sheet is among the most widely applied ferrous metal. With fast economic development, it is more and more widely used in roofing, interior decoration and advertising. Generally there are two ways to polish a sheet: physical polishing and chemical polishing.

Aluminum reflective sheet suppliers usually adopt the chemical method, which are further divided into four types.

1. Anodizing, which means to remove the alumina above the outer shell of the aluminum sheet for effective polishing.

2. Electrolytic polishing, which adopts electrolytic polishing in the use of chemical reactionas the anode. Insoluble metal is cathode immersed in the electrolytic cell and exerted on the direct current. The anodized aluminum is dissolved and disappears from sheet surface.

3. Chemical polishing can be used as a pre-treatment step for protective decorative plating, or as a pre-treatment step for chemical film formation such as phosphating. If the rust-proof passivation solution is immersed before painting, the alumina on the surface of the sheet can be eliminated.

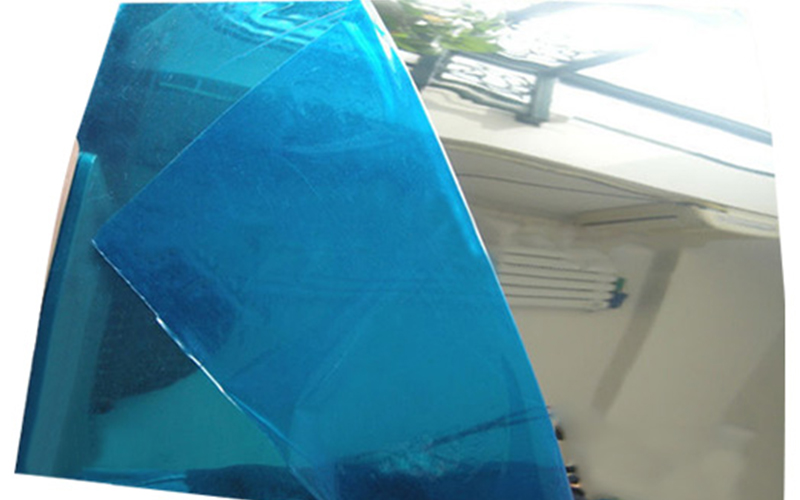

4. After the anodization of the electrolysis reaction, the color is formed, various colors are formed on the oxide film, and then coloring is performed, which is determined according to your requirements. You can also customize thickness and color, like a 1.8mm aluminium sheet glass mirror in gold or blue, and suppliers would process as you need.

Physical polishing can be carried out in the following steps.

1. First grind with a small grinding wheel that repairs the small plate of the circuit board, and then grind with the finest sandpaper.

2. Then polish successively with the following tools: Crude oil stone 400#—fine oil stone 600#—fine sandpaper 800#—metallographic sandpaper W5—grinding paste polishing.

Nydia

Nydia

Sales Manager

Sales Manager