Polished Aluminum Plate Building Materials

September 23, 2021

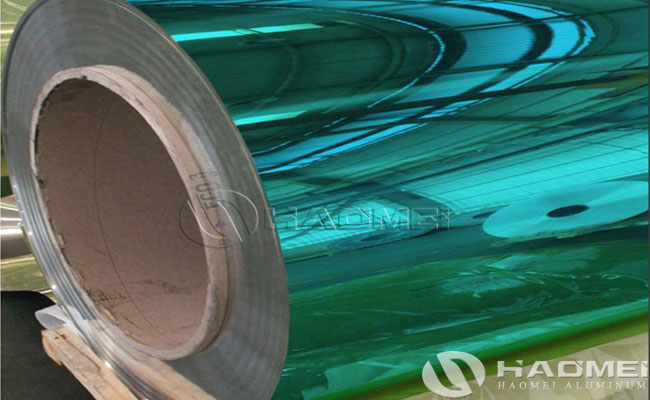

Mirror polished aluminum plate building materials are high-end aluminum, and the main aluminum alloy used are 1050 aluminum, 1060 aluminum, 3003 aluminum and 1100 aluminum. The reflectivity of mirror polished aluminum sheet is as high as 98%, the cleanliness is high, and the surface is flat. Haomei Aluminum has a variety of low, medium and high-grade mirror aluminum sheet as building materials, which are widely used in lighting reflectors, solar heat collection reflective materials, electronic product housings and other industries.

The mirror polished aluminum plate building materials has a variety of colors, and the lighting reflect effect is good, and it has strong reflection ability. In building materials and car decoration, mirror polished aluminum plate is often used to highlight the shape and overall structure, increase beauty and promote individuality. The material is light, which reduces more energy consumption. For example, mirrored polished aluminum sheet are more commonly used in construction and decoration, which are not only beautiful in luster, but also not easy to oxidize. The aluminum material is light in weight, has fewer joints on the board surface, and has high precision, it has a long service life and low cost, it has a high load-bearing capacity and a good construction effect, at the same time, it has a high recycling value.

The surface of polished aluminum plate building materials is protected, and the mirror surface rate will not change with time. It is divided into two grades: 86% ordinary mirror surface and 95% super mirror surface. Anodized mirror finish aluminum sheet play an important role in construction. Many well-known buildings are now in use, because the texture of the metal color is very good, and it looks quite tall. The oxidized surface is combined with the inside. During use, there is no need to worry about unsafe factors, and no poisonous gas will be released, which is very environmentally friendly. After the treatment of the process, the aesthetics has increased a lot, and there is also anti-corrosion performance. These advantages have been recognized by the majority of engineers and are favored by many consumers.

Nydia

Nydia

Sales Manager

Sales Manager