Aluminum Gutter Roll

September 26, 2021

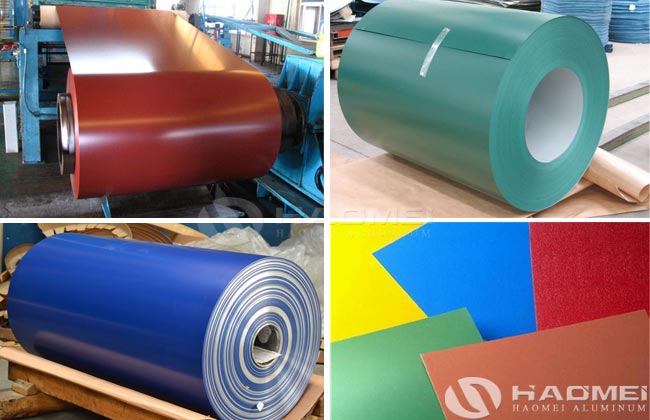

The aluminum gutter roll adopts 1000 series of pure aluminum, 3000 series of aluminum-manganese alloy, and 5000 series of aluminum-magnesium alloy. The thickness of aluminum gutter coil is divided into 0.6mm, 0.7mm, 0.8mm, 0.9mm, 1.0mm, 1.1mm, 1.2mm, 1.5mm, etc. The electrostatic powder spray paint process provides high-quality protection and decorative effects of aluminum gutters. The magnesium and silicon contained in aluminum are more anti-corrosive, with higher impact resistance, and no worries about water leakage and deformation.

The surface of the aluminum gutter roll is treated with 7 processes including special cleaning, soaking, pickling, drying, anodized anti-corrosion treatment, primer, topcoat, and 200°C constant temperature baking. The color outdoor polyester coating is electrostatically sprayed and 200°C constant temperature baking, the coating thickness of aluminum gutter coil is not less than 20um. The weather resistance of the coating is not less than 5 years, high weather resistance, high hardness, abrasion resistance and impact resistance, meeting the export environmental protection requirements. The thickness deviation of the aluminum coil material is not more than 0.02, the length deviation is not more than 5%6, and the wall thickness of the seamless downspout is not less than 0.7.

Gutter raw material are aluminum gutter roll, the specification is:

Substrate: 3003, 3105 aluminum alloy

Coating: outdoor polyester electrostatic powder spraying process or outdoor polyester paint baking process

Anti-corrosion: anodized anti-corrosion treatment on the inner wall (the same treatment process for aluminum alloy doors and windows). Twenty years of no corrosion on the surface (has passed the 1000-hour neutral salt spray test of the National Testing Center (1000-hour salt spray test is equivalent to putting the material in seawater for 5 years without corrosion). 20 years of paint in harsh weather environments There is no change in visual inspection, and the surface of the base material has not been corroded for 20 years.)

Nydia

Nydia

Sales Manager

Sales Manager