Product Categories

- Aluminum Coil (49)

- Aluminum Strip (29)

- Aluminum Tread Plate (23)

- Aluminum Foil (13)

- Aluminum Slugs (4)

- Aluminum Sheet (46)

- Aluminum Profile (16)

- Aluminum Circle (21)

- Color Coated Aluminium (22)

- CTP Plates (3)

Alloy: 8011 3105

Surface: mill finish

Temper: H14, H16, H18

Thickness: 0.15-0.28mm

Application: wine ropp caps, cosmetic pp caps, pharmaceutical closures, beverage covers etc.

enquiryAn aluminium sheet for bottle cap can be made of raw material of 1 series, 3 series, 5 series and 8 series of mill finish aluminium coils, including 8011, 3105, 1060, 3104 and 5052. Bottle cap aluminum sheet coils win great popularity because aluminum sheets bottle caps has light weight, outstanding deep drawing property and good sealing effect. Haomei has 8011 and 3105 bottle cap aluminum sheet coil rolls of direct casting and continuous casting. Our products are applied to bottle cap making of various products, such as wine ropp caps, cosmetic pp caps, pharmaceutical closures, beverage covers and so on.

| Alloy | Temper | Thickness (mm) | U.T.S (Mpa) | Elongation(%) | Earing (%) |

| 8011 | H14,H16 | 0.15-0.28 | 125-155 | ≥2 | ≤2 |

| 3105 | H14,H16 | 0.15-0.28 | 150-200 | ≥1 | ≤2 |

| Alloy | Temper | Thickness (mm) | U.T.S (Mpa) | Elongation (%) |

| 8011 | H16 | 0.15~0.25 | 160~215 | ≧2 |

| 8011 | H18 | 0.15~0.25 | 220~260 | ≧1 |

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ni | Ti | Other | Al | |

| Each | Total | |||||||||||

| 3105 | 0.6 | 0.7 | 0.3 | 0.3~0.8 | 0.2~0.8 | 0.2 | 0.4 | – | 0.1 | 0.05 | 0.15 | Remain |

| 8011 | 0.50~0.9 | 0.60~1.0 | 0.10 | 0.20 | 0.05 | 0.05 | 0.10 | – | 0.08 | 0.05 | 0.15 | Remain |

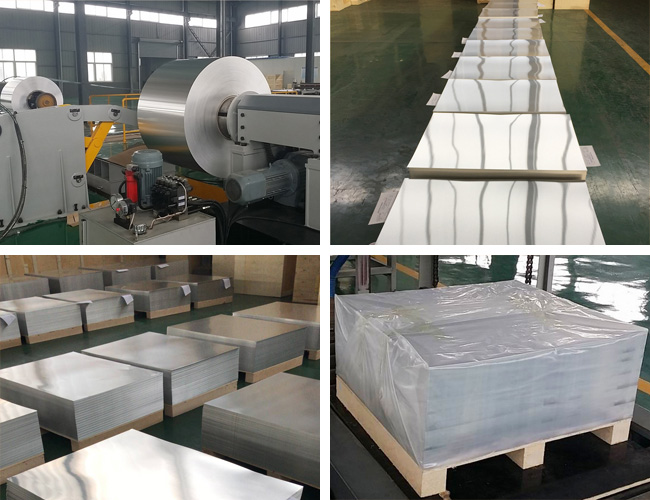

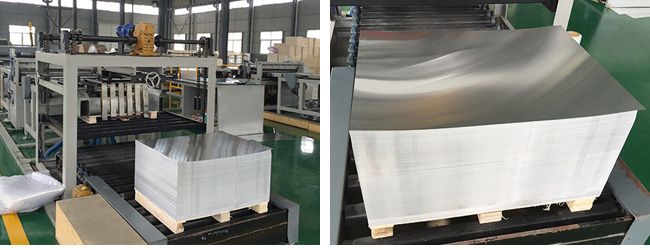

Haomei realizes its quality control of aluminium sheet for bottle cap in the following ways.

A: Strictly control various performance parameters of raw materials, including strength, elongation and dimensional deviation requirements.

B: During the rolling process, the surface quality should be checked at least once every 3 coils, and the surface quality should be checked for each coil of the finished product pass.

C: The finished product must pass strict cap stamping test.

The following products were judged as unqualified:

1. The surface is not smooth;

2. There are cracks, bubbles or through pores on the surface;

3. There are metal and non-metal press-in on the surface;

4. There are light and dark stripes on the surface;

5. The slices have burrs, knife back prints or ruffles;

6. Cracks or creases appear in the stamping test.

Haomei precision integrated plate profile control system can compete with that of Mingtai, and helps to guarantees quality of our bottle cap aluminum sheets.

The aluminium sheet for bottle cap must be made of top quality bottle cap aluminum sheet coil by a highly automatic production line. It’s applied to bottle caps of various beverages, alcohol, medicine and health care, cosmetics, snacks and other products.