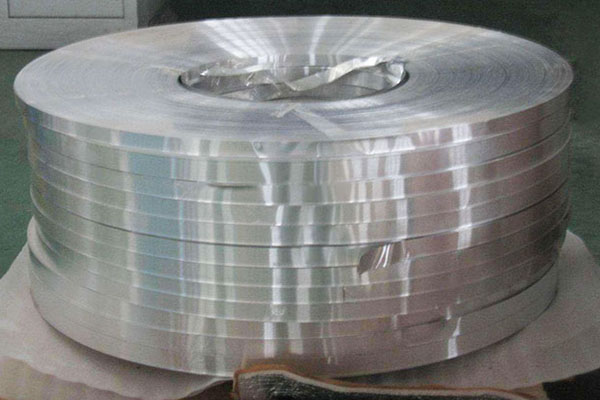

Slitting of thin aluminium strips

October 12, 2019

In slitting of thin aluminium strips(thickness of 0.2-0.3mm), higher requirements are posed, for the edge defects of the aluminum strip are easily excluded in the slitting process. A ruffled edge refers to a narrow wave of lotus leaf shape on the strip edges formed during slitting owing to inappropriate contacts among the blade, the rubber ring and the flattening roller.

In the process of slitting thin aluminum strips, the tool or flattening roller should be re-adjusted every time the ruffle defect occurs. Every time it is adjusted, the head should be re-drawn to guarantee smoothness of the strip belt. Ruffled edges of strips not only affect the production efficiency but also reduce the yield, for no finished aluminium strip rolls can be regarded as qualified once they have lotus leaves on the edges.

All kinds of surface quality problems appearing in the slitting and slitting process of the aluminum strip must be solved one by one, which ensures the smooth surface and zero burr of the finished aluminum strip. In the modern industrial automation today, the aluminum strip cutting process also enters the automation sequence. The control of the large slitting and slitting unit is adopted, and the strict program parameters are set. Automatic production lines make it easy to realize the mass production of the thin aluminium strips. Guaranteeing production speed and process level, their application is an indispensable technology in the modern aluminum processing industry.

Nydia

Nydia

Sales Manager

Sales Manager