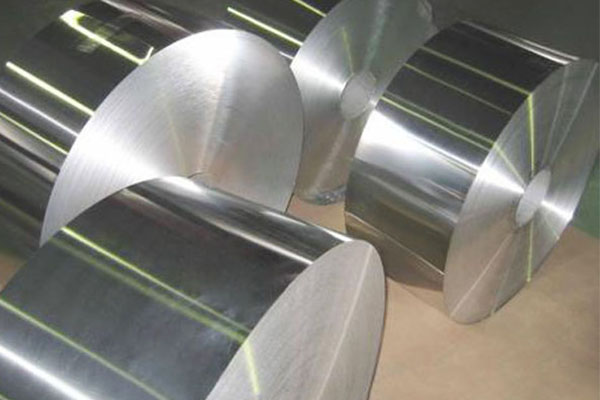

Slitting of 1mm 2mm 4mm aluminium strip

October 12, 2019

What kind of machine is used to make aluminum sheets into 1mm 2mm 4mm aluminium strip belts? Many people might think about a shearing device, but they are actually dealt with by a continuous slitting unit of a similar working principle to that of a shearing device. The difference lies in the point that there is no pause of shearing with a continuous slitting unit. Generally, the mother roll, namely, an aluminum coil to be slit, is placed. During the slitting process, the coil roll is divided into several belts which are further rolled into narrow aluminium strip rolls.

The slitting method of both 1mm 2mm 4mm aluminium strip or other aluminum strips can be divided into two types: a straight pull type and a loose sleeve type. The straight pull type refers to the method that aluminum strip rolls are kept in tension from being fed into the unwinding sail to being coiled by the coiling machine, and this production method is suitable for trimming and intermediate slitting. The loop type is that the aluminum strip forms a pan sleeve between the vacuum table and the disc shear in the machine row, and is stored in the looper to make it in a relaxed state, and the other sections are still in a state of tension, and the production method is suitable for both trimming and slitting.

In the slitting process, the ratio between the aluminum and the slit is determined according to the specifications of the strip. The temper and thickness of aluminum strips are different, and the ratio of the slit is also different. For example, the O state is soft, the tear ratio is small, and the shear thickness is 70%. However, the H state is hard, the tear ratio is large, and the shear ratio is small, about 30%.

Nydia

Nydia

Sales Manager

Sales Manager