3003 Aluminum Sheet Price Analysis

December 19, 2025

In the current global aluminum market, 3003 aluminum sheet is attracting increasing attention from customers due to its superior performance and wide range of applications. According to the latest market data, the international market 3003 aluminum sheet price is approximately between $3,000 and $3,500 per ton. This price fluctuation is influenced by various factors, including raw material costs, transportation costs, and market demand. As a typical Al-Mn series rust-resistant aluminum alloy, the price positioning of 3003 aluminum sheet is highly correlated with its material properties, processing difficulty, and wide applicability, which is the core reason for its stable demand in the international market.

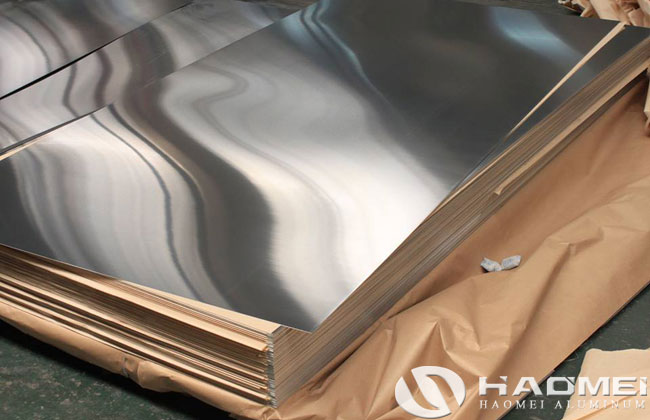

From a material perspective, the manganese content of 3003 aluminum sheet is controlled within the range of 1.0-1.5%, ensuring that the material’s rust-resistant performance is superior to that of pure aluminum series while retaining excellent cold-working formability and weldability. It can meet the mechanical requirements of most industrial applications without the need for heat treatment strengthening. Haomei Aluminum produces 3003 aluminum sheets covering all tempers from O and H12, H14 to H38, with thicknesses ranging from 0.2-8mm, widths customizable up to 2650mm, and lengths up to 16000mm. This flexible specification capability allows for cost adaptation to different procurement needs—for example, 0.2-0.5mm thin aluminum sheets can be used for small-batch precision electronic heat sinks, while 2650mm wide sheets can be used for large-batch building curtain walls or automotive skins to reduce splicing waste.

From a cost-value balance perspective, the price advantage of 3003 aluminum sheets is particularly prominent in low- to mid-range aluminum alloy applications. Compared to 5052 series high corrosion-resistant aluminum alloys, its cost is reduced by approximately 15-20%, while its corrosion resistance is sufficient to meet the needs of conventional industrial environments, building exteriors, and food packaging. Compared to 6061 series heat-treatable aluminum alloys, although its strength is slightly lower, its processing costs are reduced by more than 30%, making it perfectly suitable for the production of stamped and bent parts without high strength requirements. International market data shows that the demand for 3003 aluminum plates in fields such as new energy vehicle power battery casings and brazed water cooling plates has reached 35%. This demand stems from its cost-performance balance. Our 3003 mod series, developed specifically for this field, can be directly brazed with 4343/4045 alloys, further expanding its application scenarios in heat dissipation systems.

Under current pricing conditions, the cost advantage of bulk purchasing is even more significant. Our factory’s container-level bulk purchasing solution for export orders can achieve a 10-15% price reduction while ensuring product tolerance control within ±0.02mm and surface roughness Ra≤0.8μm. Application feedback indicates that 3003 aluminum sheet has a service life of over 15 years in fields such as marine pipeline insulation, chemical equipment containers, and wide-width roof panels. Its rust resistance has been verified through salt spray testing, and its corrosion resistance level meets the level 9 requirements of standard. Given the current stable trend in international aluminum prices, the 3003 aluminum sheet price is relatively controllable, making it undoubtedly one of the best choices for international customers who seek cost-effectiveness and application reliability.

Nydia

Nydia

Sales Manager

Sales Manager