Stucco embossed aluminum coil classification and application

July 17, 2020

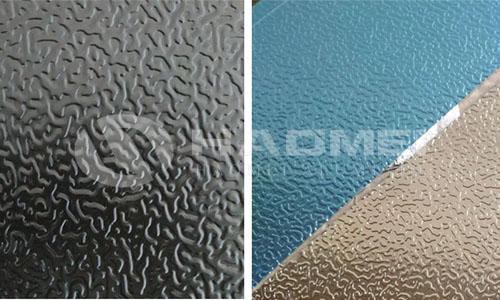

A stucco embossed aluminum coil, better known as an orange peel or insect pattern aluminum coil in China, is subdivided into classic orange peel aluminum coil and variant orange peel aluminum coil. The former is more popular abroad and the latter enjoys more popularity at home. Standing out from China aluminum coil suppliers, Haomei Aluminum can process stucco aluminium coil in the thickness range of 0.09-1.0mm and width to 1550mm, with 1100 1060 1050 3003 3004 3104 5052 as its regular alloys. Both aluminium and paper hard barrel cores are available for foreign orders. We offer vertical free For fumigation packaging or horizontal packaging, the orange peel aluminum coil must have a barrel core during processing. The diameter of the barrel core is 505mm, both aluminum and paper.

Stucco embossed aluminum coil suppliers classify their products first according to alloy composition. The orange peel aluminum sheet can be divided into: high-purity aluminum sheet (rolled from high-purity aluminum with a content of more than 99.9), pure aluminum sheet (composition is basically rolled from pure aluminum), alloy aluminum sheet (Consisting of aluminum and auxiliary alloys, usually aluminum copper, aluminum manganese, aluminum silicon, aluminum magnesium, etc.) composite aluminum plate or aluminum welding plate (a special purpose aluminum plate material obtained by means of multiple materials composite) and so on.

Stucco embossed aluminium rolls are called orange peel rolls because their pattern resemble that of orange peels. Serving as a regular material for fridge inner walls, air conditioning heat exchanging units and ordinary packaging, the coil rolls also find their applications in lighting, solar reflectors, architectural appearance, interior decoration, furniture, cabinets, elevators, signs, nameplates, automotive interior and exterior decoration, interior decorations, household appliances, insulation pipe coating and other industries. There’s no doubt that with development of modern science and technology, these application scopes will be further widened in the future.

Nydia

Nydia

Sales Manager

Sales Manager