Solution to Gloss Problems of Painted Aluminum Coil

January 25, 2019

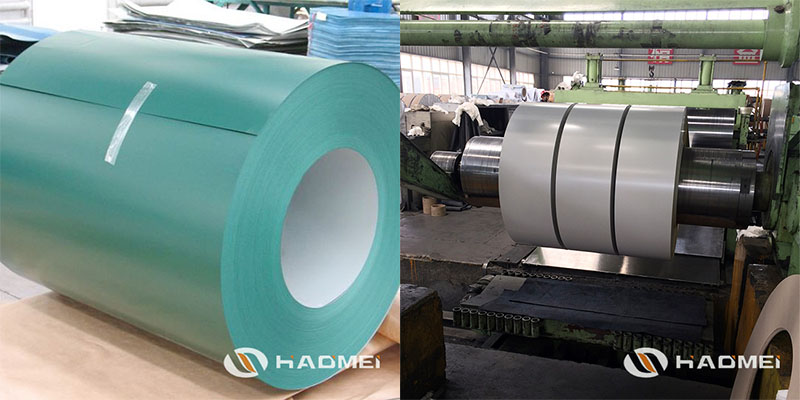

As a composite material with multiple chemical elements, color painted aluminum coil rolls are extensively applied in various industries. However, a typical problem complained by not a few users is that color coated aluminium materials they use are lacking in enough gloss, which makes them less attractive than they actually should be. Generally there are two reasons for this: process problem and chemical composition problem. Here we provide solutions.

Solution to Process Problem

1. The method to solve the matte surface problem is to reasonably set the furnace temperature of each stage of the curing furnace to avoid the furnace temperature being too high or too low.

2. Check that the fineness of the coating on the machine meets the process requirements.

3. The paint should be mixed and filtered before it is put on the machine. The diluent cannot be used too much.

4. Control the humidity between the rolls to prevent moisture from mixing into the coating.

5. Check that the diluent matches the coating so that the wet film thickness of the surface coating is not too thin.

Painted emboss aluminum roof coil rolls are commonly used in cans, electronics, aluminum ceilings and other products. To make them as decorative as possible, painted aluminum coil suppliers add many chemical components in the rollers. To solve this problem, we can take some measures to restore them to their original state.

Chemical Composition Rules

1. Most of the colour coated coil rolls contain 0.2% zirconium and titanium.

2. To set appropriate numerical obstacles, the observations or calculated values obtained from the analysis are based on standard rules to indicate a clear range.

3. Unless a range or a low value is listed, the combined element attributes are represented by a high value.

4. The content of aluminum in unrefined non-alloyed aluminum is the difference between the total amount of other metals and pure aluminum – the difference is 0.01% or slightly larger, and two decimal places in the ratio of 100 parts.

5. In addition to pure aluminium, the elements specified in a color coated aluminium coil are usually indicated in the analysis report, but if other elements are suspected to be unnecessary during the analysis or if some elements are suspected to be excessive, further analysis should be carried out until a definite answer is obtained.

Nydia

Nydia

Sales Manager

Sales Manager