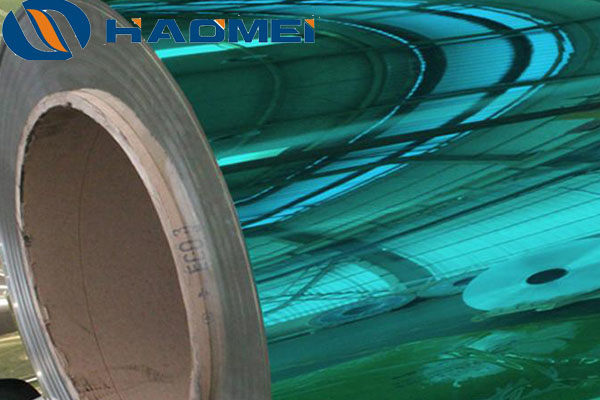

Mirror aluminum sheet 3003

March 19, 2020

Mirror aluminum sheet 3003 ranks middle by quality in all alloys of aluminium mirror sheets. It overshadows 1050, 1060, 1070 and 1100 in either hardness or corrosion resistance, but can not compete with 5005, 5757, 5052 and 5083 in the two aspects. 3003 mirror sheets are used extensively in solar reflective panels, light reflective covers and ornaments, interior decoration, exterior decoration, home appliance panels, electronic product housing, kitchen furniture and decoration, automobile ornaments, logos, labels, jewellery cases and so on.

3003 aluminum mirror sheet is a member of Al-Mn alloy, containing up to 1.5% manganese, 0.6% silicon, 0.2% copper, 0.10% zinc and 0.7% iron. The remaining part is aluminium. It has a tensile strength between 120 and 160Mpa, and a conditional yielding strength 85 and above. Haomei supplies 3003 mirror sheets of thickness from 0.1mm to 4mm and width up to 2200mm. Reflectivity ranges between 85% and 95%. The higher the reflectivity, the higher the price. Different reflectivity levels are obtained by varied surface treatment methods.

There are two surface treatment methods for 3003 mirror sheets: mechanical polishing and anodizing. The former is carried out by having a sheet polished repeated with a polishing machine until its surface gets bright and reflective enough. The latter adopts both mechanical and chemical methods. A sheet, placed in chemical solutions, functions as the anode while the solution acts as the negative pole, and its reflective surface is obtained during the anodizing process. Generally speaking, anodizing produces aluminum sheets of better quality and reflectivity. This method even enables manufacturers to color coating the sheet, producing gold mirror aluminum sheet, red aluminum mirror sheet and so on. Of course, the price of colored mirror sheets are higher. It’s worth mentioning, however, that 3003 aluminum sheet is not the best raw material for anodizing process, 5754 and 5052 prove to boast better anodizing effect. Most high end electronic products that adopt mirror aluminium as housing, therefore, are equipped with 5xxx mirror sheets.

Nydia

Nydia

Sales Manager

Sales Manager