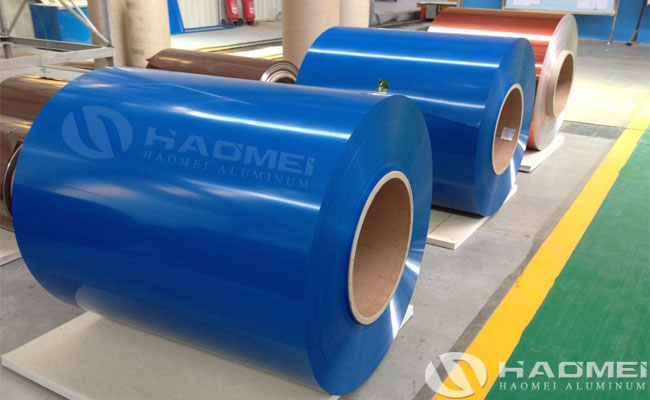

Metal Roofing Coil Stock

August 7, 2023

Aluminum-magnesium-manganese metal roofing coil stock is a cost effective roofing and exterior wall material. Aluminum coil stock is widely used in the construction industry and has played an important role in the development of modern architecture towards comfort, lightweight, durability, economy, and environmental friendliness. AA3004 aluminum-magnesium-manganese alloy is widely recognized as a roofing and exterior wall material with a design life of over 50 years, due to its moderate structural strength, weather resistance, stain resistance, and ease of bending, welding, and processing. For architectural designs in marine climates, the more corrosion-resistant 5052 marine grade aluminum alloy can be chosen.

The outstanding advantages of metal roofing coil stock offer by Haomei Aluminum are:

- Lightweight: Aluminum has a density of 2.73g/cm3, only one-third of steel.

- High strength: High strength can be achieved through composition configuration, processing, and heat treatment methods.

- Corrosion resistance: Aluminum roofing coil has self-rust prevention ability and forms an oxide layer to prevent metal oxidation and corrosion, with good acid and alkali resistance.

- Diverse and beautiful surface treatments: Anodizing, electrophoresis, chemical treatment, polishing, and painting treatments are available.

- Good plasticity and easy processing.

- Good conductivity: Non-magnetization and low sensitivity to electric sparks can prevent electromagnetic interference and reduce flammability in special environments.

- Easy installation: Aluminum can be connected by riveting, welding, adhesive bonding, etc.

- Environmental friendly, 100% recyclable.

The metal roofing coil stock produced by Haomei Aluminum has high quality and longer service life, the coating process is twice to improve surface performance against rain water and sunlight. General two-coating and two-baking color treatment process: 1. Unwinding → 2. First coating → 3. First baking → 4. Second coating → 5. Second baking → 6. Cooling and storage → 7. Quality inspection → 8. Rewinding → 9. Reverse winding and reinspection → 10. Packaging.

Nydia

Nydia

Sales Manager

Sales Manager