How to Test Aluminium Disc Earring Rate

March 11, 2019

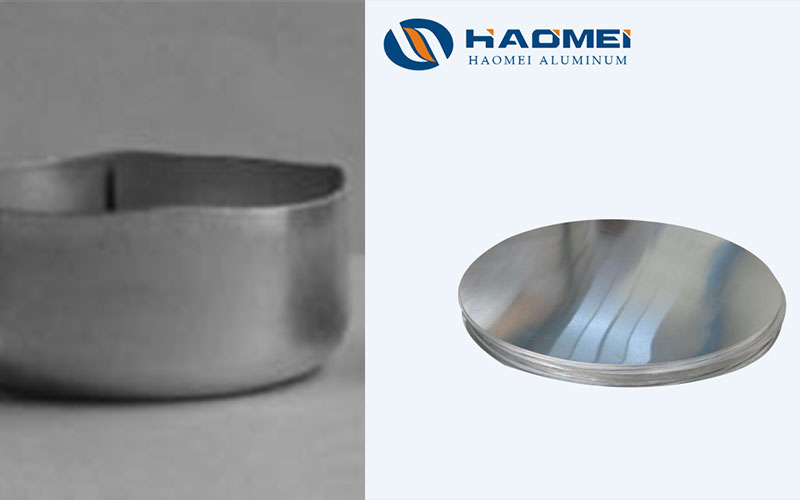

As a crucial factor reflecting the quality of an aluminium disc, earring rate is attached to great importance to purchasers. Although it takes energy and time to make aluminum blanks into aluminium discs, high earring rate would wipe out all your effort in one day. Thus both manufacturers and purchasers do an earring rate test before large-scale production or buying.

Earring test method

1. Sample preparation. According to the standard requirements, prepare aluminium circle 1050 samples and accurately measure the thickness of the disc;

2. Select the mold according to the thickness of the aluminium disc;

3. Ear test equipment: screen display automatic cupping test machine.

3. During the earring test, the disc circle sample is pressed between the die and the bead ring, and the sample is drawn through the punch to form an empty cup. After the test, the characteristics of the lugs at the cup mouth were measured, and the ear rate was calculated as an index to evaluate the degree of plastic plane anisotropy of the metal sheet. In this test, the control of the blanking force will determine the success of the ear test. If the blank holder force is not properly controlled, wrinkling or cracking usually occurs. Of course, the smaller the draw ratio, the easier it is to make the earring test.

4. Measure the ear height and the ear height of the cup, the measurement accuracy is ±0.05mm, and read the average ear height hp and the average ear height hv.

6. Calculate the rate of ear production. For the cup with obvious ear, calculate the ear rate. The calculation method is:

In hp-hv e= hv where hp-hv is the average ear height. ×100%

Nydia

Nydia

Sales Manager

Sales Manager