How to Guarantee the Effect of Oxide Film on Aluminum Mirror Sheets

February 21, 2019

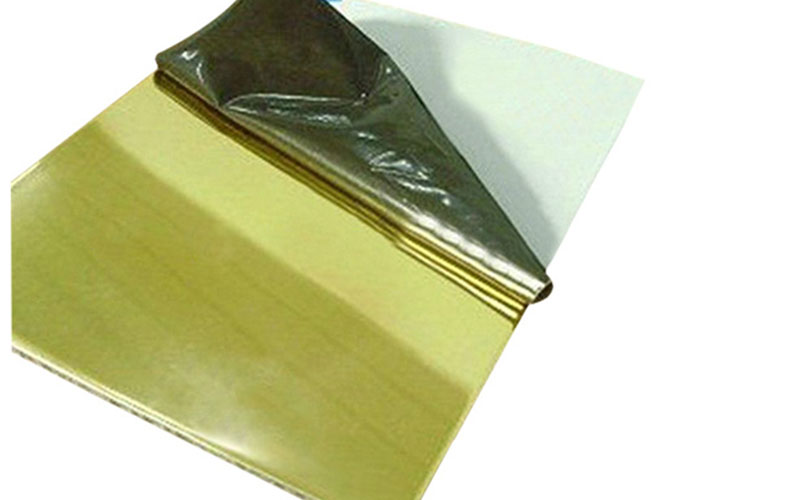

The mirroring effect of an aluminum mirror sheet depends on quality treatment of both substrates and oxidation films. The surface of a substrate itself should reach a given reflectivity, and the matching oxide film should be highly pure and transparent. Here we would like to share how to guarantee the effect of oxidation film on a polished aluminum plate.

At present there are three types of oxide films for mirror finish aluminum products: Oxalic acid oxide films, chromic acid oxide films and sulfuric acid oxide films. The former two are of colored type, so they are naturally unclear. Thus the only one worth considering is the sulfuric acid oxide film. Main factors affecting the transparency of a sulfuric acid film include its purity, thickness, porosity and sealing quality. If there are too many impurity ions or atoms (like silicon/manganese/iron/copper/chromium) in the oxide film, the purity of the film will be low and the transparency will decrease. Impurities lead to light scattering loss of the film. Transparency also decreases with the increase of oxide film thickness. Pinholes are the main source of light scattering, and the higher the porosity, the more light scattering. Especially when the pinholes are markedly horn-shaped, the light scattering will increase sharply and the transparency will decrease rapidly. The sealing material for the oxide film is boehmite, and there are nickel hydroxide and fluoroaluminate in case of sealing at room temperature. Both nickel hydroxide and fluoroaluminate are transparent, so normal sealing will not reduce the transparency of oxide film. However, if the hole has been sealed, all the frost formed will become light scattering particles, which will greatly reduce the transparency of the oxide film.

Based on the information above, to improve the transparency of the oxide film, we should focus on four aspects: improving the purity of the oxide film, controlling the thickness of the oxide film, reducing the porosity of the oxide film, and ensuring proper sealing.

Nydia

Nydia

Sales Manager

Sales Manager