How a Make a Simple Knurling Roll for Embossed Aluminium Coil

March 13, 2019

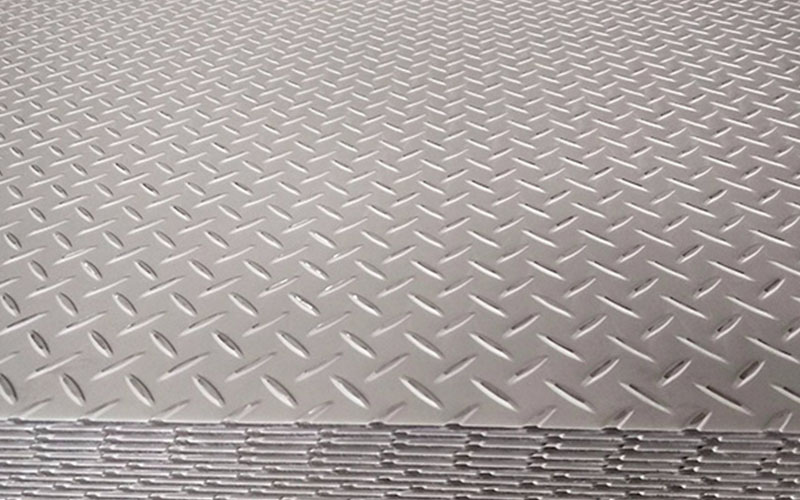

Embossed aluminium coil sheet is a product obtained by rolling and knurling of aluminum rolls, used extensively in packaging, building and curtain walls etc. The knurling of an embossed sheet is carried out by a knurling roll of the desired pattern. For example, a hammered plate can only be obtained by putting the substrate through a hammered-pattern roll. In addition, different rolls deal with coil sheets of varied thicknesses. Therefore, an embossed aluminium coil sheet manufacturer usually needs to exchange rolls frequently to meet requirements of various embossed patterns and thicknesses, which undoubtedly raises equipment cost. Here we introduce a new type of knurling roll that is featured by a simpler structure, a wider application scope and an evener embossing effect.

The new model of aluminum embossed sheet coil roller device comprises a support frame and two embossing rollers. The support frame consists of an upper beam, a lower beam and a column. The column is connected with the upper beam and the lower beam. The upper beam and the lower beam are arranged in parallel, and the column is perpendicular to the column. The upper beam and the lower beam are respectively provided with adjustment grooves that are superimposed on the horizontal plane. The embossing roller comprises a roller and a pattern sleeve, both of which can be dismantled and connected. Each of the connecting ends of the embossing roller respectively passes through the adjusting grooves of the upper beam and the lower beam, and is vertically fixed to the upper beam and the lower beam by bolt connection. This aluminum embossed sheet coil roller device can adjust the spacing between the two embossing rollers according to the thickness of the processed aluminum plate, and the pattern sleeve can be adjusted and arranged on the roller to realize double-sided embossing and single-sided embossing. The dual function has the advantages of simple structure, wide application range, uniform embossing and low use cost.

Nydia

Nydia

Sales Manager

Sales Manager