Buy aluminum sheet mirror polish here

August 22, 2019

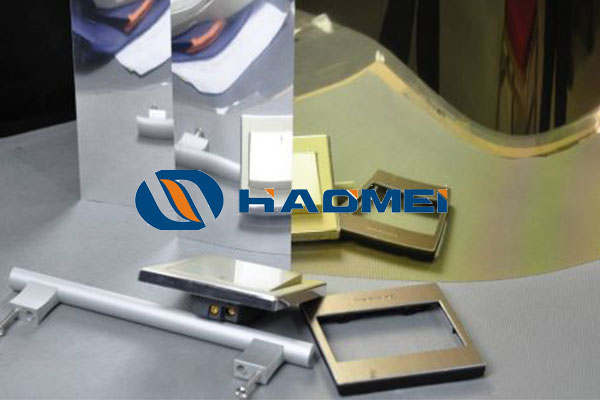

The “aluminum sheet mirror polish” is a phrase created by clients’ searching way, the product is called mirror polish aluminum sheet actually. A aluminum plate can be mirrored after being polished and polished. The mirrored aluminum plate has a strong anti-corrosion effect, because aluminum is oxidizing and can form a dense aluminum oxide film on the surface, which can protect the internal material. The surface of the aluminum mirror sheet is as smooth and reflective as the mirror surface, so it is specially used for making reflectors, such as the reflector of the lamp panel and the reflective surface of the LED spotlight, which are made of mirror aluminum. Mirror aluminum plate has beautiful and practical characteristics. In addition to lamps, it has performed well in interior decoration materials, furniture materials, electronic product casings, etc. It is also widely favored in the fields of electronic products, household appliances panels, luggage, etc. In a word, it’s a strongly applicable material.

In production of aluminum sheet mirror polish, the sheet is usually mechanically polished first, and then goes through chemical polishing or electro-chemical polishing. The traditional triacid chemical polishing, due to the presence of nitric acid, produces a large amount of yellow NO2 gas during production, which is highly toxic and seriously pollutes the environment. The improved triacid chemical polishing also produces a large amount of white smoke, which is also very polluting to the environment. In recent years, the chemical polishing of diacids has not produced toxic gases because no nitric acid is added, but the polished aluminum profiles have a slightly poorer surface brightness than tri-acid polishing or electrochemical polishing. Traditional electrochemical polishing requires the addition of chromium ions, which seriously pollutes the environment. The polishing process used has a current density of 20 to 30 A/dm2, which wastes energy. Now, Haomei uses electrochemical polishing technology based on phosphoric acid and adding polishing agent. It is smoke-free, non-toxic, energy-saving, low current density, no emission, and can be used for a long time.

Nydia

Nydia

Sales Manager

Sales Manager