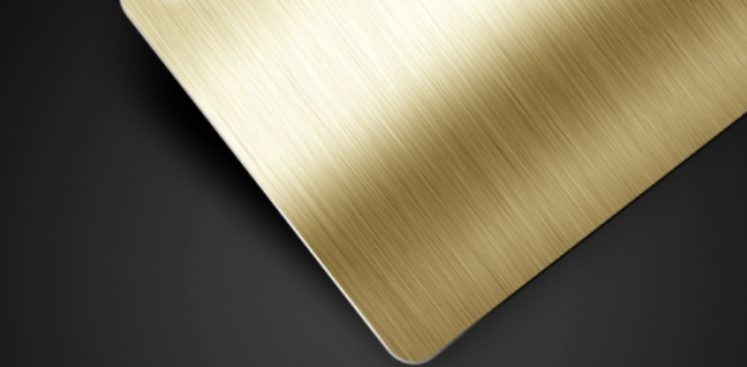

Anodized Brushed Gold Aluminum

May 27, 2022

The anodized brushed gold aluminum has strong decorative properties and moderate hardness. It can be easily bent and formed for continuous high-speed stamping, which is convenient for direct processing into products without complicated surface treatment, which greatly shortens the product production cycle and reduces product production costs. Brushed anodized gold aluminum plate are widely used as home decoration materials.

Anodizing is a common chemical surface treatment process for aluminum plates. Anodized brushed gold aluminum have good corrosion resistance, anti-static insulation properties, and good adhesion and adhesion if the surface is not sealed (composite, such as aluminum-based copper clad laminates, aluminum honeycomb composite board, fireproof composite board), strong anti-fouling performance, no fingerprints. The thickness of the oxide film of the anodized aluminum sheet can generally be between 3um and 15um. Of course, the thicker the oxide film thickness, the better the performance and the higher the price. The gold anodized aluminum plate with quasi-thick oxide film (3μm) will not discolor, corrode, oxidize or rust in indoor use for a long time. The anodized gold aluminum plate with thick oxide film (10μm) can be used outdoors and can be exposed to sunlight for a long time without discoloration.

Anodized brushed gold aluminum is beautiful, the gold color anodized have good decoration effect. The colors of the double-sided brushed aluminum plate include matt color, bronze color, green, red, silver, gold, bronze, with cypress and other colors. Anodized brushed aluminum are used in lighting, office furniture veneer, cabinet veneer, indoor and outdoor high-end decoration, automotive interior and exterior decoration, household appliances, electronic product shells, signs, jewelry boxes and other related industries.

Nydia

Nydia

Sales Manager

Sales Manager