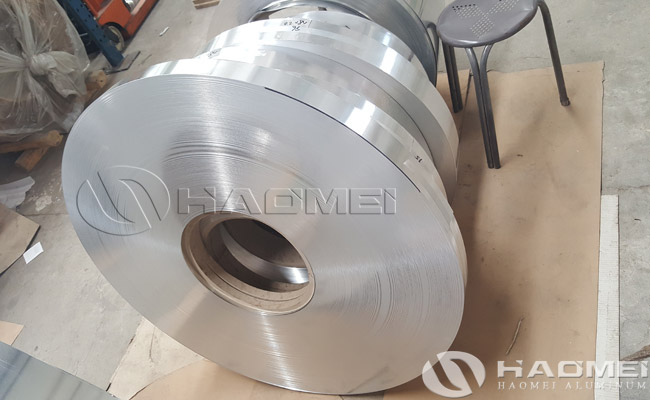

Aluminum Strip For Industrial Use

November 18, 2025

Industrial aluminum strip is a widely used aluminum product in various industrial fields, typically used in manufacturing and processing. Aluminum strip boasts advantages such as lightweight, high strength, corrosion resistance, good electrical and thermal conductivity, and ease of processing. The specifications, thickness, and width of aluminum strip can be customized according to customer needs. Common aluminum alloy grades include 1060, 1070, 1100, 3003, 3004 and 5052.

The following are the main applications of aluminum strip for industrial use:

- Electronics and electrical industry

Capacitor manufacturing: Aluminum strip is the core material of electrolytic capacitors. It is etched to form aluminum foil with a high specific surface area, serving as the anode of the capacitor for power filtering, energy storage, and other applications.

Heat dissipation components: Aluminum strip has excellent thermal conductivity and is often used to make heat sinks and fins, ensuring efficient heat dissipation in electronic devices (such as CPUs and LEDs).

Cable aluminum strip: Used for cable shielding or insulation, it has good conductivity and oxidation resistance. This type of aluminum strip typically has high purity to ensure good conductivity.

Shielding materials: Aluminum strip can be processed into electromagnetic shielding covers for use in mobile phones, computers, and other devices to prevent electromagnetic interference (EMI).

Battery connector: In lithium-ion batteries, aluminum strip serves as the positive electrode current collector, connecting the battery tabs to the external circuit to ensure stable current transmission.

Transformer aluminum strip: Aluminum has lower conductivity than copper, but it has lower density, is lighter, and relatively cheaper. Aluminum windings are increasingly being used in high-power transformers.

- Packaging industry

Food packaging: After lamination or coating, aluminum strip is used to make aluminum foil containers, can lids, chocolate packaging, etc., providing moisture-proof, oxygen-barrier, and freshness-preserving functions.

Pharmaceutical packaging: Aluminum strip is used in blister packaging (PTP aluminum foil) for pharmaceuticals, protecting them from light, moisture, and oxygen, extending their shelf life.

Industrial packaging: Aluminum strip can be processed into aluminum coils for wrapping and protecting pipes and cables, or for making rust-proof packaging materials.

- Construction and decoration

Curtain walls and roofs: After rolling and coating, aluminum strip is made into aluminum panels or aluminum coils for building curtain walls and roof decoration, combining aesthetics and weather resistance.

Interior decoration: Aluminum strips can be processed into ceilings, partitions, decorative moldings, etc., meeting the modern building requirements for lightweighting, fire resistance, and moisture resistance.

Signage: Patterns can be printed or etched onto the surface of aluminum strips for use in billboards, road signs, doorplates, etc.

- Transportation Industry

Automotive manufacturing: Aluminum strips are used in automotive radiators, air conditioning condensers, fuel tanks, and other components to reduce vehicle weight and improve fuel efficiency.

Aerospace: Due to its low density and high strength, aluminum strips are used in aircraft skins and structural components to reduce aircraft weight.

Rail transit: Aluminum strips are used in decorative panels and floors of high-speed rail and subway cars, as well as shielding layers for electrical wiring.

- Machinery manufacturing and industrial equipment

Heat exchangers: Aluminum strips are the core material for evaporators and condensers in refrigeration equipment such as air conditioners and refrigerators, utilizing their high thermal conductivity to achieve heat exchange.

Pipeline systems: Aluminum strips can be made into aluminum-plastic composite pipes for transporting water, gas, etc., offering corrosion resistance and easy installation.

Sealing materials: Aluminum strip, when combined with rubber and plastic, is used to make sealing strips and gaskets to ensure equipment sealing.

- New energy field

Solar photovoltaics: Aluminum strip is used as a backsheet material for photovoltaic cells, protecting the cells and improving power generation efficiency.

Wind power generation: Aluminum strip is used as a reinforcing rib or skin for wind turbine blades, improving structural strength.

Energy storage equipment: Aluminum strip is used in battery energy storage systems to connect electrodes and heat dissipation modules, optimizing system performance.

- Other applications

Printing and labeling: The surface of aluminum strip can be printed or hot-stamped for making high-end labels and anti-counterfeiting marks.

Crafts and daily necessities: Aluminum strip can be processed into aluminum tableware, stationery, decorations, etc., to meet daily needs.

The wide application of industrial aluminum strip is due to the following characteristics:

Lightweight: Its density is only 1/3 that of steel, making it suitable for weight-sensitive fields.

Corrosion Resistance: The surface easily forms an oxide film, adapting to humid and chemical environments.

Processability: It can be rolled, stamped, and welded to meet complex shape requirements.

Environmental friendliness: Recyclable, meeting sustainable development requirements.

With advancements in industrial technology, the applications of industrial aluminum strip continue to expand, with demand growing in emerging fields such as 5G communications and new energy vehicles.

Nydia

Nydia

Sales Manager

Sales Manager