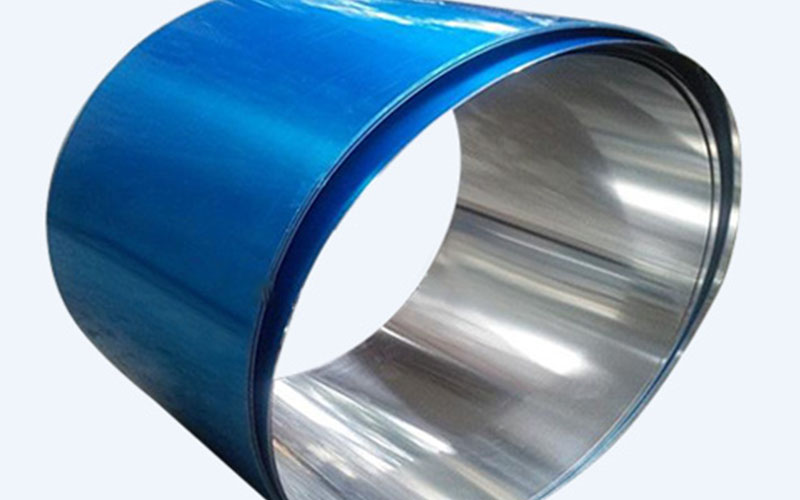

Aluminium Strip Coating Process

March 4, 2019

This is about aluminium strip coating process. Aluminum coil rolls are fed, slit, combined with previous strips, coated, cooled and sent for storage.

1. In strip stirring process, the raw material of aluminum coil rolls with sleeve are transported to the coil brackets at the entrance of uncoiler by a crane or other tools, and then the coil is lifted by a trolley and installed on the uncoiler for uncoiling;

2. Thin aluminium strips are cut through the end of the pinch roll and sewed into the tails of the the upper strips, and then sewed by a corner trimmer. The closing part is rounded, and then the tension tensioner is used to enter the looper tower (the production line equipped with strip trimmer and pull-off machine must be trimmed and straightened first).

3.When the reel is changed, the entrance section stops and the entrance looper tower feeds new rolls onto the production line while the whole line keeps normal working speed. When the new material reel head and the tail of the material reel are combined, the looper tower rises to the current working speed. After the reaches the normal material length, the speed of the entrance section decreases to the positive working speed again;

4. If the aluminium strip 1mm leaves the entrance looper, it will be cleared, settled and treated, and then the air knife enters the cloth room to carry out the swimming layer of the strip after curing. The curing temperature of the strip after curing to curing the coating is 20 C.

5.After the brushed aluminium strip is cooled by air cooler, water chilled charge and air knife, surface finishing and static oil are applied. Then the strip passes through the outlet looper tower and enters the exit section. The exit section includes a checking table for checking the appearance quality of the strip. When the coiling reaches the specified length, weight or diameter, the exit section stops, while the unit processing section continues to operate at the normal working speed, the outlet is alive at this time. Sleeve tower functions to store strips.

6.Finished aluminum strip rolls are unloaded by export coil trolley and transported to the coil storage bracket. At the same time, after the coiler has completed the threading and established stable tension, the belt coiler returns and the speed of the outlet section rises to the required working speed.

7.When the outlet loop tower reaches the normal storage length, the speed of the outlet section falls back to the normal working speed. At the same time, the section length of the minimal volume looper with the maximum Double-Ground method is usually equipped with two uncoiled and slab-type solution bearing axle structures. The external axle-compression supporting mechanism is used to set up aluminum strip rolls storage bracket and unloading sleeve in front of the machine.

Nydia

Nydia

Sales Manager

Sales Manager