Aluminium Strip 1mm Used for Stamping Parts

December 17, 2018

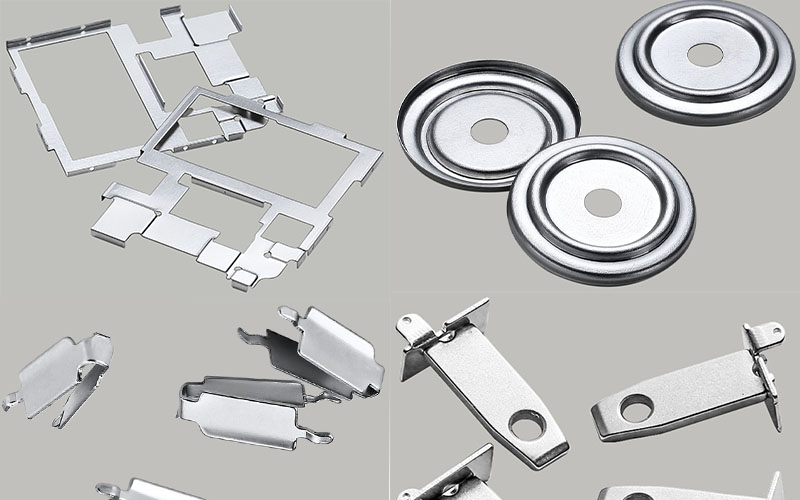

One of the application scope of aluminium is for stamping parts. Large-sized aluminum sheets can be made into bodies of vehicles, oil tanks and aircraft parts. Aluminium strip 1mm, on the other hand, are usually punched into smaller parts for electronic products, art crafts and table ware etc. Typical products include SIM card holding pieces in cell phones, battery shells, bottle caps for cosmetics, key chains, table plates, basins, home appliance button and so on. In a word, aluminium strip 1mm mainly serves as a raw material for small portable products requiring little about strength.

Generally speaking, all regular alloys of 1000, 3000 and 5000 series can be made into aluminium strip 1mm. Strength and corrosion resistance of each of the three series gets stronger successfully. Aluminium strip has light weight, good processing adaptability and long durability. With a small density only one third of steel, it’s suitable to be made into portable items carried around. Aluminum is endowed with a natural ability of corrosion resistance, which does not mean that it’s inactive as a chemical element. In contrast, it’s so active after being exposed to the air that a layer of oxide aluminum swiftly comes into being on the surface of any alu piece surface without special coating processes. What’s amusing is that this thin layer of oxide material performs strong resistance to most corrosive chemicals. That’s why we say aluminum has a natural corrosion-resistant ability. The good processing adaptability of aluminium strip 1mm refers to its strong adaptability to so many existing processing methods for regular metals. Stamping and deep drawing are among them. In comparison with iron, aluminium has a longer durability, because it does not get rusty and collapsed as iron would do after long-term exposure to the air.

Nydia

Nydia

Sales Manager

Sales Manager