Aluminium Slug for Tubes

June 6, 2018

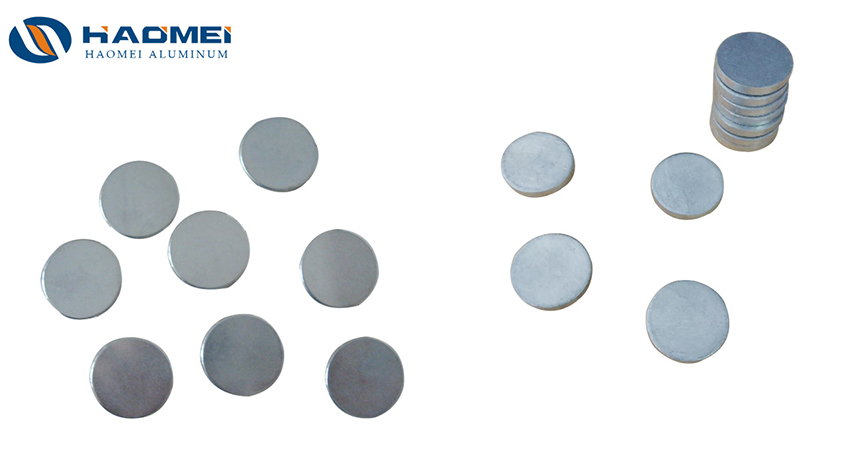

Aluminium slug for tubes is obtained by cold punching of thick aluminum strips. In other words, aluminum ingots are first processed into aluminum plates which are further cut into narrow strips for cold punching. Aluminum slug for tubes cover a wide range of shapes. There are round, rectangle, elliptic, dome and irregular shapes for special applications. Slugs of all these shapes can be drilled with holes.

The raw material for aluminium slug for tubes are usually aluminum alloy 1050, 1070 and 3003 etc. Diameter of the tubes ranges from 10mm to 200mm and thickness from 2mm to 30mm. To guarantee surface quality of the slugs, raw materials have to go through treatments of mill finish, tumbling, shot blasting etc. Aluminium slug for tubes have perfect mechanical properties, making them ideal materials for further processing. Their tensile strength reaches around 69mpa and ductility 40%. They can be processed into tubes for pharmaceutical packaging and cosmetic packaging, cans for beverages and aerosols as well as shells for electric capacitors and fire extinguishers.

Haomei aluminum, an integrated aluminum alloy manufacturer, supplies aluminium slug for tubes, aluminum discs, aluminum sheet and aluminum coil of various specifications. We have over twenty years of manufacturing history and fifteen years of exporting experience. Our products and service have won popularity with clients from all over the world. Welcome to contact us at april@aluminumhm.com or 0086 15838029491 (mobile, wechat, whatsapp, skype) for more information!

Nydia

Nydia

Sales Manager

Sales Manager