Advantages of 3003 aluminum painted emboss coil for roofing

September 7, 2020

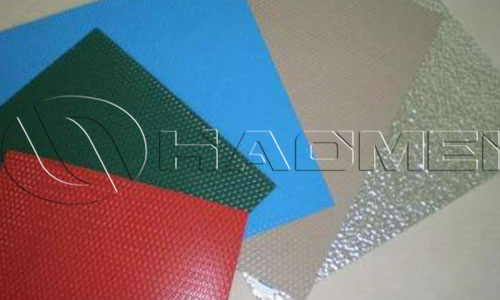

3003 aluminum painted emboss coil for roofing is water-proof, heat insulating, uv resistant and light.

3003 aluminum coil serves as an excellent cookware material. Aluminium pots made of it are used to boil and contain water as a daily household item. Therefore, aluminium has a natural water-proof ability regardless of its alloys and grades. While being used as a roofing material, 3003 aluminium coil is usually processed on the surface to obtain a better water-proof ability.

The embossed pattern of the coil refracts light more effectively than smooth surfaces of aluminium roofing sheets. This not only disperses most of the light, including ultraviolet light, trying to penetrate into the roofed space, but also keeps temperature in the space in a relatively stable level. That’s why aluminium roofing is known to have the function of thermal insulation.

3003 aluminum coil has a long service life by itself. After it’s painted and embossed, the coating layer helps to extend its service life considerably. The thicknesses of our 3003 embossed aluminum color coat coil are: 2.0mm, 2.5mm, 3.0mm, 4.0mm. The coil is treated with fluorocarbon spraying. The polyvinylidene fluoride (KANAR500) content of fluorocarbon paint topcoat and protective paint>=70%, generally divided into two coatings, three coatings and four coatings are most commonly used as three coatings, and the coating thickness is 40~ 50um.

Aluminium is the lightest of all ordinary building materials, which proves to be competitive for this greatly reduces bearing weight of the roof and the whole building.

Nydia

Nydia

Sales Manager

Sales Manager