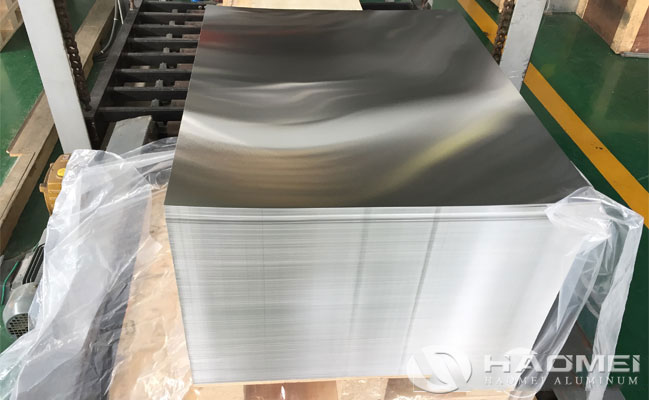

1000 Series Aluminum Sheet Plate

December 29, 2025

As a technician with many years of experience in aluminum sheet production, I firmly believe that the core value of the 1000 series aluminum sheets lies in the adaptability and reliability brought by their high-purity aluminum substrate. 1000 series belongs to the pure aluminum product category, and aluminum content is its core technical indicator. Except for a small amount of unavoidable impurities, the mass fraction of the main alloy component, aluminum, is no less than 99.0%, which is the fundamental characteristic that distinguishes it from other alloy aluminum sheets.

Looking at commonly used grades in the 1000 series aluminum sheet, 1050, 1060, 1070, and 1100 are currently the mainstream in the market. Among them, 1060 aluminum sheets have an aluminum content of ≥99.6%, balancing performance and cost, and are the most widely used grade; 1070 aluminum sheets have an aluminum content of ≥99.7%, belonging to the high-purity series, and are more suitable for scenarios with strict requirements on material purity; 1100 aluminum sheets, due to the presence of trace amounts of iron and copper, are slightly superior in strength to the former two, making them suitable for working conditions with certain requirements on formability.

In terms of production process and specifications, our 1000 series aluminum sheets are all produced using continuous casting and cold rolling processes, ensuring uniform sheet structure and a smooth surface. The specifications cover a comprehensive range, with thicknesses from 0.2mm (ultra-thin foil substrate) to 10.0mm (thick plate), widths can be customized according to customer needs, with a standard range of 1000mm-2600mm, and standard lengths of 2000mm-6000mm. Special sizes can be achieved through custom rolling. It is worth noting that for thin sheets with a thickness ≤0.5mm, we use high-precision cold rolling mills, controlling the thickness tolerance within ±0.01mm, fully meeting precision machining requirements.

Characteristics and technical advantages of our 1000 series aluminum sheet are:

– Excellent corrosion resistance:

Based on the properties of high-purity aluminum, the corrosion rate in atmospheric, freshwater, and neutral media environments is much lower than that of alloy aluminum sheets; the naturally formed oxide film on the aluminum surface is dense and has strong adhesion, effectively preventing the intrusion of corrosive media.

– Excellent electrical and thermal conductivity:

Represented by 1060 aluminum sheet, it boasts an electrical conductivity of up to 62% IACS and a thermal conductivity of 238 W/(m·K), making it an ideal material for electrical and thermal applications.

– Excellent plasticity and formability:

It can be bent, stamped, stretched, rolled, and other forming processes, adapting to the processing needs of complex working conditions.

– Good weldability:

Compatible with various welding methods such as argon arc welding and resistance welding, the weld joint strength can reach more than 85% of the base material strength, ensuring reliable splicing.

– Flexible and adjustable hardness:

Through optimized annealing processes, the hardness can be precisely adjusted between the O temper (soft state) and the H18 temper (hard state), matching the strength requirements of different processing scenarios.

Typical application scenarios of 1000 series aluminum plate:

– Electronics and electrical industry:

Utilizing its excellent electrical conductivity, it is used to manufacture transformer and capacitor housings and conductive busbars, ensuring the stability of electrical transmission.

– HVAC industry:

Based on its high thermal conductivity, it serves as a core material for air conditioning heat exchangers and radiators, significantly improving heat exchange efficiency.

– Packaging industry:

Ultra-thin aluminum sheets can be processed into aluminum foil for food and pharmaceutical packaging, offering both barrier properties and safety.

– Construction industry:

Its corrosion resistance makes it ideal for interior decorative panels and ceilings, ensuring long-term use without discoloration or deformation, combining aesthetics and durability.

– Chemical industry:

Suitable for neutral media environments, it’s used to manufacture storage containers and pipelines, ensuring the safety of media storage and transmission.

– Aerospace industry:

Its high purity meets precision requirements, making it a base material for precision instrument components, ensuring instrument operational stability.

For users, choosing 1000 series aluminum sheets requires careful consideration of their specific operating conditions: If electrical and thermal conductivity is prioritized, grades 1070 or 1060 are preferred; if a balance between strength and formability is needed, grade 1100 is more suitable; for precision machining, high-precision products with a thickness tolerance ≤ ±0.02mm are recommended. As a professional aluminum sheet manufacturer, we can provide comprehensive technical support, from grade selection and specification customization to processing technology adaptation, tailored to each customer’s specific application scenario, ensuring products accurately meet actual needs.

Nydia

Nydia

Sales Manager

Sales Manager