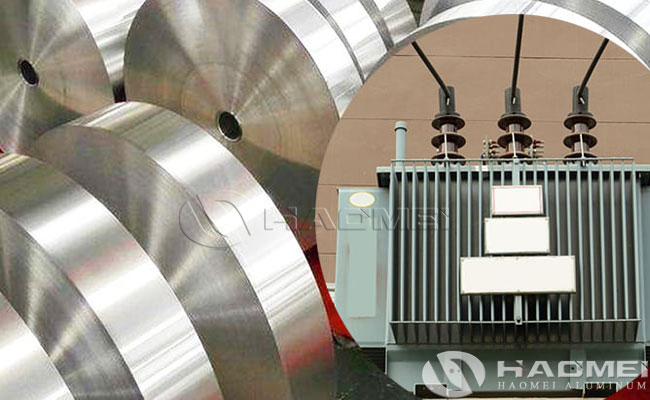

Round Edge Transformer Aluminum Strip

October 28, 2025

Round edge transformer aluminum strip is a key material used in transformer windings. Its core feature is a specially processed edge structure with rounded corners or edges, designed to optimize performance and adapt to specific applications. Compared to copper strip, aluminum strip is lighter and less expensive, making it widely used in certain applications.

The base material of round edge transformer aluminium strip is primarily industrial-pure aluminum (grades such as 1060-O, 1070, and 1350), with an aluminum content exceeding 99.6%. It exhibits high electrical conductivity (≥62.5% IACS), thermal conductivity, and corrosion resistance. Its density is only one-third that of copper, significantly reducing weight and cost by 30%-50% compared to copper strip.

Specifications and Performance of round edge transformer aluminum strip:

– Thickness: 0.2-3.0mm, Width: 20-1650mm. Edges can be processed to rounded corners or edges, with no burrs and a surface roughness of ≤0.5μm. Resistivity: ≤0.028Ω・mm²/m, approaching internationally advanced levels, meeting the low-loss requirements of high-efficiency, energy-saving transformers.

– Mechanical Properties: Tensile strength 60-135MPa, elongation 15%-30%. Ductility can be further optimized through annealing.

– Edge Treatment Advantages: The rounded edge design avoids the risk of tip discharge associated with traditional rectangular aluminum strip, reduces insulation damage between turns, and improves winding stability, making it particularly suitable for automated high-speed winding equipment.

Features of rounded edge transformer aluminum strip:

– Lightweight: Aluminum has a lower density than copper, allowing it to reduce the overall weight of the transformer.

– Cost-Effectiveness: Aluminum is generally cheaper than copper, offering cost advantages.

– Conductivity: Although aluminum’s conductivity is lower than copper, it can still meet transformer performance requirements within certain designs and applications.

– Oxidation Resistance: Aluminum easily forms an oxide film on its surface, providing a certain degree of corrosion resistance.

Manufacturing processes of round edge transformer aluminum strip

– Smelting and Casting:

High-purity aluminum ingots are used for smelting, with the casting and rolling temperature controlled at 680±5°C. Grain size is maintained at a stable 25-30μm, ensuring material uniformity.

– Rolling and Annealing:

Multiple cold rolling passes are used to reduce thickness, combined with a step-wise annealing process (e.g., 320°C for 30 minutes) to improve conductivity while balancing mechanical strength.

– Surface Treatment:

Anodizing: An insulating oxide layer (approximately 1-5μm thick) is formed on the aluminum strip surface, reducing the use of inter-turn insulation material and improving winding compactness.

Environmentally Friendly Coating: An aluminum-silicone-fluorocarbon composite coating is used, which cures at room temperature and offers strong weather resistance. It can replace traditional high-temperature baking coatings and meets environmental requirements.

– Quality Control

Online monitoring systems (such as machine vision) detect surface defects in real time, with an accuracy rate of 96.5%, reducing the frequency of manual spot checks.

Thickness deviation (≤3.2%) and resistivity consistency are strictly controlled to ensure stable product performance.

Application Scenarios of round edge transformer aluminum strip:

– Power Systems

Dry-Type Transformers: Round edge aluminum strip windings reduce transformer size by 30% and weight by 40%, while also meeting flame retardancy and low partial discharge (≤3pC) requirements. They are widely used in high-rise buildings, underground facilities, and commercial centers.

Oil-Immersed Transformers: 1350 alloy aluminum strip, which can withstand temperatures up to 130°C, is used in the inner windings of large power transformers, reducing manufacturing costs.

– New Energy Sector

Photovoltaic and Wind Power: In photovoltaic projects, amorphous alloy aluminum windings in box-type transformers reduce costs by 35% and no-load losses by 70% compared to copper windings, driving cost reduction and efficiency gains in new energy projects.

Energy Storage Systems: Aluminum strip winding transformers are used in energy storage converters, supporting high power density designs and adapting to the rapid charging and discharging requirements of lithium batteries.

– Rail Transit

Metro systems using amorphous alloy aluminum winding transformers reduce no-load losses by 66%, while also improving short-circuit resistance and operational stability. Industry and Home Appliances

High-frequency aluminum strip transformers are used in industrial inverters, reducing their size by 50% and increasing their efficiency to over 96%. In home appliances (such as air conditioners and televisions), aluminum strip windings can reduce electromagnetic interference and optimize energy efficiency.

Round edge aluminum strip for transformers, with its advantages of low cost, lightweight, and easy processing, holds a significant position in the power, new energy, and industrial sectors. With the advancement of energy-efficient policies and the advancement of manufacturing processes (such as environmentally friendly coatings and automated winding), aluminum strip is poised to further replace copper strip and become the mainstream material for medium and low voltage transformers.

Nydia

Nydia

Sales Manager

Sales Manager