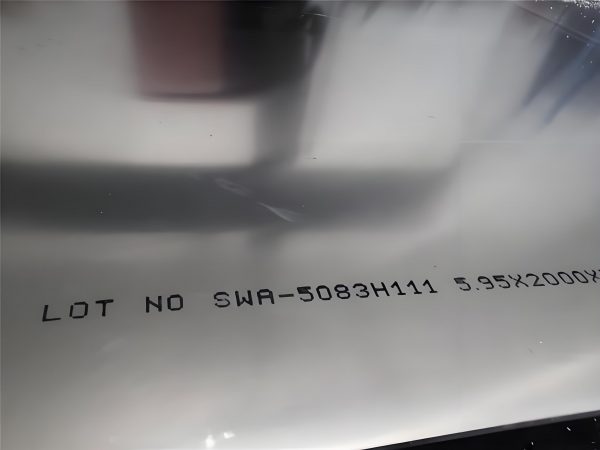

Aluminium Alloy 5083 O H111

October 22, 2025

Aluminium 5083 o h111 alloy plate is a high-strength, highly corrosion-resistant aluminum-magnesium alloy plate belonging to the 5xxx series aluminum alloys (Al-Mg series). It offers excellent overall performance, particularly in marine environments and welded structures.

Chemical Composition and Alloy Properties

– Main Composition:

Magnesium (Mg) is the primary alloying element (approximately 4.0-4.9%), with small amounts of silicon (Si) and iron (Fe), and the remainder is aluminum (Al).

– Key Advantages:

Corrosion Resistance: The high magnesium content provides excellent resistance to seawater, salt spray, and industrial atmospheric corrosion, making it suitable for harsh environments.

Weldability: It can be welded using processes such as TIG, MIG, and laser welding, with weld strength exceeding 80% of the parent metal. 5356 or 5183 welding wire is recommended.

Low-Temperature Toughness: It maintains excellent toughness even at ultra-low temperatures of -196°C, making it suitable for extreme operating conditions such as LNG storage tanks.

TemperAnalysis: The Meaning of O and H111

– O temper:

This indicates a fully annealed state, characterized by the highest plasticity and lowest strength, making it suitable for complex forming processes requiring extensive processing.

– H111 temper:

Processing: Cold working is followed by incomplete annealing, preserving some work hardening. The strength lies between the O and H112 temper.

Property Balance: Tensile strength of 270-350 MPa, yield strength ≥125 MPa, and elongation ≥15%, offering a good balance of formability and structural strength.

Compared to H112: H111 has slightly lower strength than H112 (H112 has a tensile strength ≥275 MPa), but higher elongation, making it more suitable for welded structures requiring a certain degree of formability.

– Typical Mechanical Properties

Tensile Strength (MPa):O: 170-240, H111: 270-350;

Yield Strength (MPa) :O:≥70. H111≥125;

Elongation (%) :O:≥22, H111≥15;

Hardness (HB):O:50-65,H111:70-85;

Implementation Standard:O:EN 485-2, H111:ASTM B209.

Core Applications of Aluminium Alloy 5083 O H111

– Marine and Offshore Engineering:

Hull structures, decks, bulkheads, marine storage tanks, etc., ensuring long-term reliability through corrosion resistance and weldability.

Select products are certified by classification societies such as ABS, DNV, and LR, complying with international maritime standards.

– Transportation:

Railway vehicle floors, refrigerated containers, automobile chassis, and structural components require lightweighting while meeting strength requirements.

Welded components for subways and light rail require both fire resistance and corrosion resistance.

– Energy and Chemical:

LNG storage tanks, cryogenic pressure vessels, and chemical reactor linings utilize their low-temperature toughness and corrosion resistance. Oil and gas pipelines and drilling equipment, designed to withstand complex media corrosion.

– Other Applications:

Bridge structures, blast-proof walls, and military armored vehicles, combining high strength and impact resistance.

Building curtain walls and decorative materials can be treated with a fluorocarbon coating to further enhance weather resistance.

Industry Standards and Certifications

– International Standards: ASTM B209 (Aluminum Sheet and Strip Standard), EN 485-2 (Performance Standard for Aluminum and Aluminum Alloy Sheet).

– Classification Society Certifications: Common products are certified by CCS, DNV, BV, LR and ABS, ensuring safety in marine environments.

– Quality Control: The production process strictly adheres to ISO 9001 and AS9100 (Aerospace Standards), and some companies have achieved IATF 16949 (Automotive Industry Certification).

Processing and Surface Treatment Recommendations

– Forming Processes: Cold working such as bending, stamping, and drawing are possible. The recommended minimum bend radius for H111 steel is 1.5t (t is the sheet thickness).

– Welding Notes: The oxide film must be removed before welding. Using AC TIG welding can reduce the risk of thermal cracking. Natural aging can restore some strength after welding.

– Surface Treatment:

Anodizing: Improves corrosion resistance and decorative properties, suitable for architectural applications.

Painting/Powder Coating: Fluorocarbon fiber coating (PVDF) resists salt spray corrosion and is commonly used for ship hull plating.

Aluminium 5083-O H111 alloy plate, with its triple advantages of high strength, high corrosion resistance, and easy welding, has become the preferred material for offshore engineering, cryogenic vessels, rail transportation, and other fields. Its H111 state strikes a balance between formability and strength, making it particularly suitable for complex structures requiring welding. When purchasing, pay attention to the chemical composition, mechanical properties, and classification society certifications. Furthermore, select the appropriate surface treatment process based on the specific application to maximize material performance.

Nydia

Nydia

Sales Manager

Sales Manager