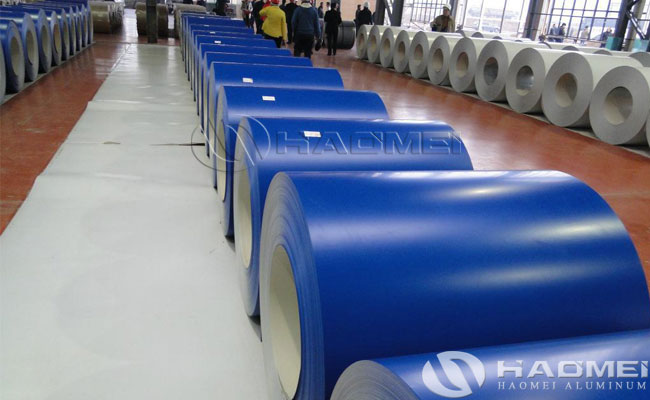

Color Aluminum Sheet Metal

August 3, 2021

Color aluminum sheet metal have wide application in building wall, shutter rolling door, caps, roofing, ceiling, decoration, gutter and license plate. The paint of color coated aluminum sheet are PE and PVDF. Polyester-coated aluminum sheet using high molecular polymer containing ester bond in the main chain as monomer, adding alkyd resin, UV absorber can be divided into matte and high gloss series according to gloss, especially suitable for interior decoration And for advertising boards.

Fluorocarbon coated color aluminum sheet metal is made by mixing fluorocarbon resin with fluorine and fluoroenyne as the basic monomer, pigments, alcohol ester solvents, and additives. After being grilled into a film at high temperature, the molecular structure in the coating is tight and has strong weather resistance. Fluorocarbon coatings can be divided into traditional fluorocarbon and nano-fluorocarbon coatings based on the appearance of film formation. They are especially suitable for indoor and outdoor decoration in public places, commercial chains, exhibitions and advertisements.

Architects, project owners and processors are thinking about the safety performance of the building (impact resistance, earthquake resistance, fire resistance, wind pressure resistance, snow resistance), housing performance (waterproof, sound insulation, heat insulation), durability (pollution resistance, durability) , Appearance persistence), economy (low cost, easy processing, easy maintenance, easy replacement), etc. For manufacturers, these properties should be converted into color coated aluminum sheet performance as a color coated aluminum manufacturer and guaranteed. Performance requests mainly include mechanical properties (tensile strength, yield strength, elongation), coating properties (coating varieties, coating thickness and coating adhesion) and coating properties (coating types, colors, gloss, durability, processability, etc).

Among them, wind resistance, impact resistance, snow resistance, earthquake resistance, etc. are all related to the mechanical properties of the material. Of course, they are also related to the wave shape of the color aluminum sheet metal, the thickness of the aluminum sheet, the span and the purlin distance. If you choose the appropriate color aluminum coil, the proper profiled steel plate design can not only meet the safety factor of the building but also reduce the project cost. The durability, processing performance and appearance persistence of materials are largely determined by the durability of the coating and plating.

Nydia

Nydia

Sales Manager

Sales Manager