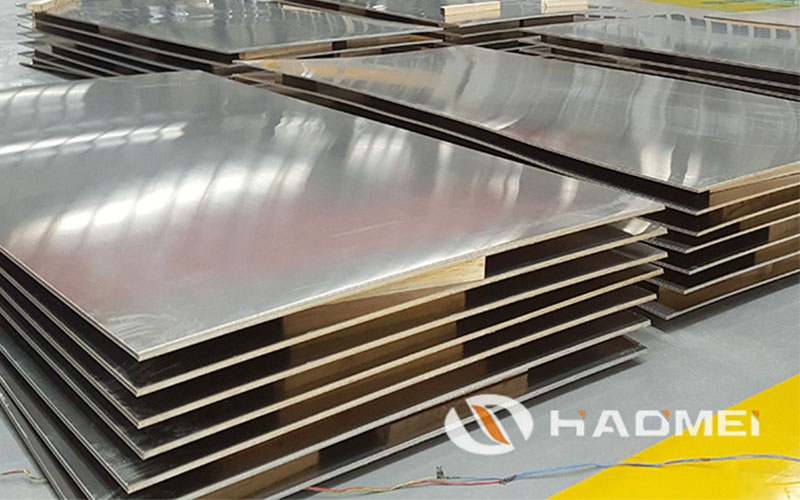

6082 Embossed Aluminum Sheet

March 6, 2019

In addition to 6061 and 6063, 6082 is another regular alloy for the embossed aluminum sheet. As a kind of aluminium alloy suitable for enhanced treatment and heat treatment, 6082 has an excellent forming property, a good welding property, a super mechanical engineering property, a medium strength and a performance kept good enough after being tempered. 6082 is similar to 6061. Both have excellent performances in extruding, casting, anodizing and corrosion resistance. After artificial seasoning, the HBS of 6082 is no less than 80 and 6061 no less than 95. 6061 and 6082 stucco embossed aluminum sheet share many usages, too, such as plane landing panels, small boats, construction parts, bicycle parts, automobile parts, instruments, rail vehicles and so on. 6082 stucco embossed finish has a stronger quench sensitivity, a better welding property and a stronger corrosion resistance, thus it’s more frequently applied in shipbuilding than 6061.

6082 embossed aluminum panels combine features of excellent weldability, brazeability, corrosion resistance, formability and machinability. The -0 and T4 states are suitable for bending and forming applications and the -T5 and -T6 for good machinability. Some specific processes entail the use of chip separators or other special processes in the separation of chips. 6082 aluminum sheet is a very common alloy in Europe and the United States, processed into raw materials, seamless aluminum tubes, structural profiles and custom profiles. Alloy 6082 usually has good processing characteristics and good anode reaction properties. The most common methods of anodic reaction include removal of impurities, dyeing, coating, and the like. Anodized embossed aluminum panels are used for mechanical parts, forgings, commercial vehicles, railway structural parts, shipbuilding, etc.

Nydia

Nydia

Sales Manager

Sales Manager