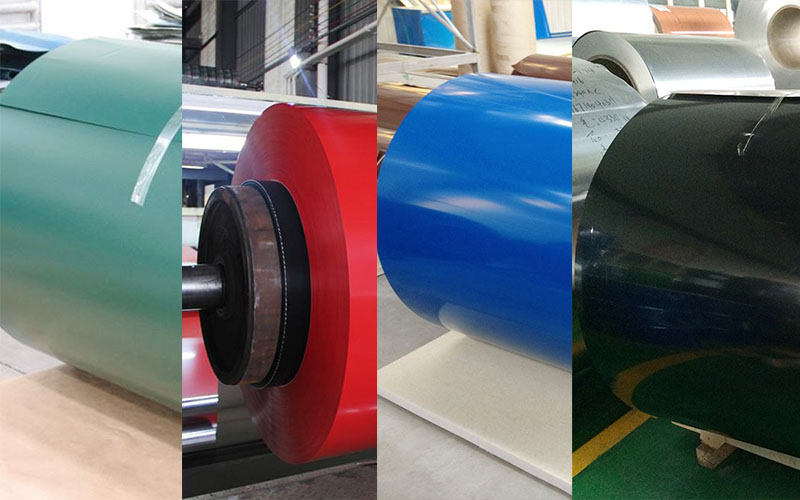

PVDF Color Coated Aluminum Coil Suppliers

January 11, 2019

Among leading color coated aluminum coil suppliers in China, Haomei provides high quality pe and pvdf color coated aluminum coil rolls of competitive prices. Colour coated aluminum is long lasting material for various indoor and outdoor applications, boasting strong acid resistance, alkaline resistance, corrosion resistance, fire resistance, water resistance, environmental friendliness and rich fresh colors lasting long under natural conditions of sunshine, frost, snow and rain. Especially, pvdf color coated aluminum coil rolls have a better performance than those of PE in the respects above. The coil rolls are applied in ACP, curtain walls, honeycomb panels, shutters, roofing, ceiling, advertising, gutters and so on. We are among aluminum coil suppliers with the latest computerized metal processing lines, the pre-treatment device of which comes from German Henkel and Kenema Mittel and PPG paint coatings from Lili Valspar in the US and Becker in Sweden. The coating of PVDF entails four steps: surface coating, self-cleaning fluorocarbon coating, polyester and acrylic coating. After over a decade of exploration of overseas market, our pe and pvdf coated aluminum coil rolls and sheets have been exported to Southeast Asia, Europe, North America, South America, the Middle East, Africa, covering over 70 countries and regions. At present we are receiving orders almost every working day, building an even bigger customer data base day by day.

Adhering to the belief of “Quality Foremost and Clients First”, we supply pe and pvdf color coated aluminum coil rolls as below. Welcome to contact us at april@aluminumhm.com for more information.

Alloy: Aluminium (AA1100, 3003, 3004, 3105, 5006, 5052, 8011, etc), etc.

Thickness: 0.08-4.0mm

Width: under 1850mm

PVDF Thickness: 25um and above

Color standard: E less than 2 or it’s not obvious by eyeballing

Pencil hardness: 2HB and above

Bend strength: 100 times and more

Boiling point: no any distortion or color change

Corrosive: surface deep in the 5% muriatic acid and 5% NaCL, interior deep in the 2% muriatic acid and 2% NaCL, after 48 hours, no change

Nydia

Nydia

Sales Manager

Sales Manager