Manufacturing Processes of Insulation Aluminum Coil

March 14, 2018

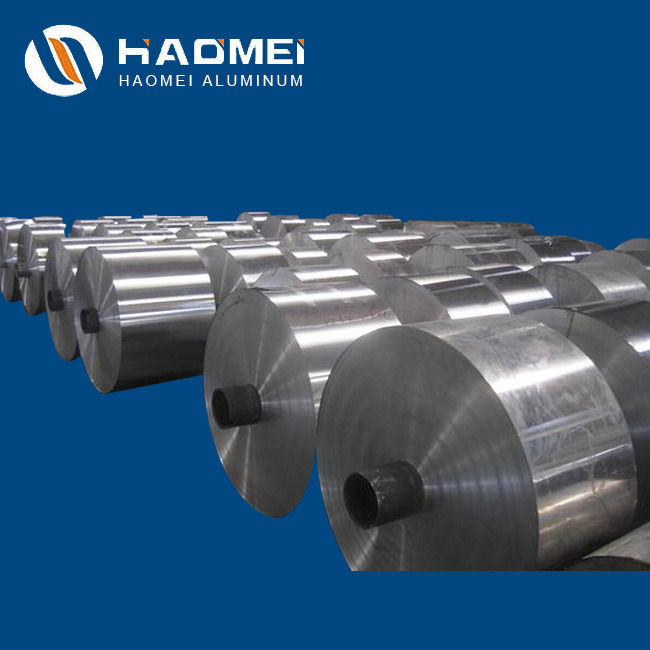

As known to all insulation aluminum coil is widely used as pipeline covers in various industries. But few people are really clear about its manufacturing processes. We will have a simple introduction today.

The first part is dosing. Exact amount of each material should be calculated in advance in accordance with concrete requirements. Wrong matching of raw materials will lead to disqualification of finished aluminum coil. Second, smelting. All raw materials, by given procedures, are put into smelting furnace. Undoubtedly there will be gas and solid waste in this part, thus a waste removal procedure is also included at the same time. Third, casting. After the melting process the raw materials turn into liquid, which is cooled and cast into coil through deep well casting system. Fourth, extrusion. The extrusive machine makes aluminum bars into coil of required thickness. Fifth, color coating. Insulation aluminum coil can be divided into pure coil and color coated coil. The manufacturing of the former does not entail color coating, but the latter can not avoid this part. The so-called color coating is actually realized by anodizing, the process of which has been explained in details in How much do you know about anodized aluminum coil. The aim of color coating is to enhance the coil’s properties like corrosion resistance, wear resistance and aesthetic degree.

Haomei Aluminum have always been sticking to its motto of “Serving Clients With Heart And Soul” and will continue to produce and provide excellent products for our clients. For new information about us, please contact us at april@aluminumhm.com and we’ll reply as soon as possible.

Nydia

Nydia

Sales Manager

Sales Manager