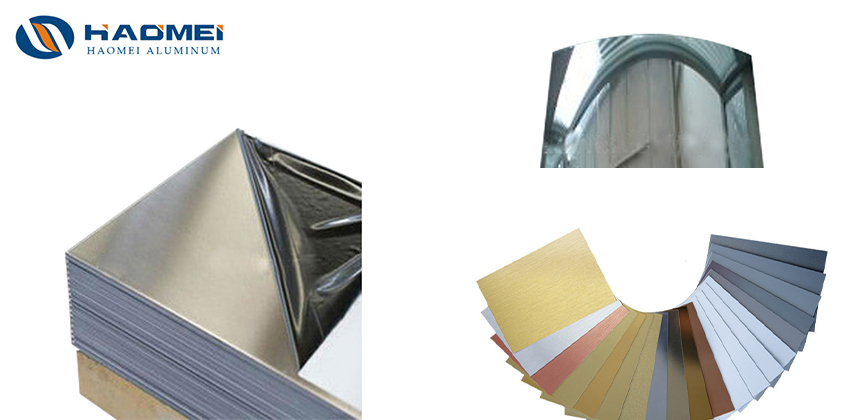

Glossiness Measurement of Mirror Finish Aluminum Sheet

July 2, 2018

The application of mirror finish aluminum sheet is closely associated with its glossiness. Generally speaking, the higher the glossiness of an aluminum mirror sheet is, the superior it is. Then how to obtain accurate gloss value of the sheets? In practice it’s usually achieved by adopting a gloss meter to measure the coating glossiness at three geometric angles respectively: 20 °, 60 ° and 85 °. Theoretically, the 60° measuring method is suitable for coatings of all gloss ranges, but its effect proves to be not so satisfying with coatings of extremely high or low gloss values. On the other hand, 20° method has strong distinguishing capability for coatings of high glossiness such as 70 units and above, and 85° method is more applicable in coatings with a gloss value of 30 units and below.

Passing through the lens, the light sources form a parallel or slightly convergent light beam toward the coating surface of mirror finish aluminum sheet. Reflected light is collected by the lens, absorbed by the photocell through the field diaphragm, and then measured by the receiver measuring instrument. The measured gloss value is in direct proportion to the luminous flux passing through the receiver. This measurement method fits only coatings of perfectly flat mirror finish aluminum sheet. Any slight bending or unevenness of the base sheet surface will affect measurement results severely.

In addition, coating thickness of the measured mirror finish aluminum sheet must be in accordance with relative rules. The tested sample sheet must be from the targeted batch. It must be clean in surface which should not be touched by hands before the test. Only in this way can we obtain an accurate glossiness of a piece of mirror finish aluminum sheet.

Nydia

Nydia

Sales Manager

Sales Manager