Differences between 3003 and 1050 aluminium circle sheet pieces

July 23, 2019

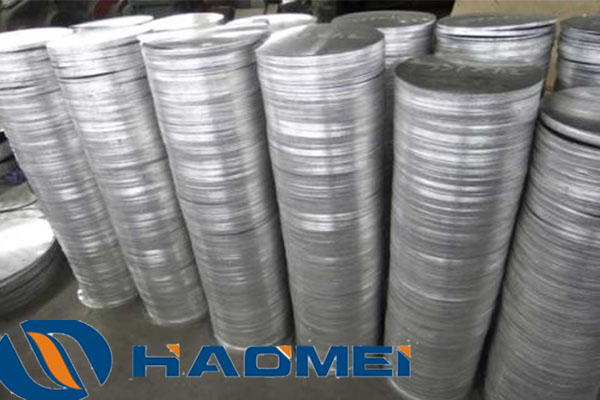

3003 aluminium circle sheet and aluminium circle 1050 are two representatives of regular aluminium wafers. In fact, most of the aluminum products we have seen are made from aluminium circle sheet pieces after secondary processing. The quality of aluminium circle sheet is relatively light and not easily corroded, so it is widely used in transportation, such as aviation, automobiles and ships. It has excellent electrical conductivity. Its conductivity is weaker than that of gold, silver and copper, but its reserves are large and its density is small. In addition, the outer oxide film of aluminum not only has corrosion resistance but also certain insulation properties, so aluminum wafer metal has very common use in the electrical appliance manufacturing industry, wire and cable, and radio industry. In recent years, with the development of the economy, various high-tech industries have also made rapid progress. Many alloy sheet and strip products, led by aluminium circle sheets, are gradually being applied to all walks of life, which greatly promotes industrial growth and economic development.

1050 aluminium circle discs are lighter and softer than 3003, often used in daily necessities, lighting fixtures, reflectors, decorations, chemical industrial containers, heat sinks, signs, electronics, lamps, nameplates, electrical appliances, stampings and other products. These products require high corrosion resistance and low strength, which makes 1050 circle a perfect choice.

The 3003 aluminium circle sheet has a better corrosion resistance than 1050 to atmospheric, fresh water, sea water, food, organic acid, gasoline, neutral inorganic salt solution, etc. Its strength is about 10% higher than 1100, and the formability, the solubility, and the corrosion resistance all good. 3003 aluminium circle sheet is used to process parts that require good formability and high corrosion resistance, or require both these properties and work with higher strength than 1XXX alloys, such as kitchenware, food, chemical processing, storage device, tanks for transporting liquid products, various pressure vessels and pipes for processing with thin plates, general fins, heat sinks, cosmetic plates, photocopier drums, marine materials and so on.

Nydia

Nydia

Sales Manager

Sales Manager