Application of Aluminium Slug for Tubes

May 18, 2018

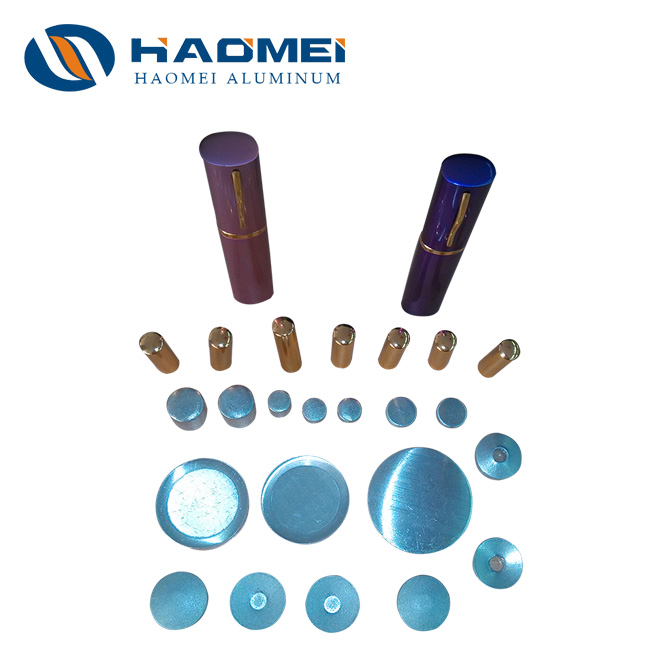

The title seems to be confusing because aluminium slug for tubes must be applied in tubes. However, it is not the case. Except tubes, it can be processed into bottles, covers and packaging materials of various shapes. Here we are going to elaborate on them one by one.

Aluminium slug for tubes can be first made into tubes for diverse contents, among which cosmetics and medical liquid prove to be the most popular. Most chemical products in pharmaceutical and cosmetic industries are corrosive to different degrees. Well-known for its excellent corrosion resistance, aluminium slug for tubes become ideal raw material for containers of such chemical liquids and lotions. In practical production of these containers, the anti-rust property of aluminum slugs gets strengthened enormously by an anodizing process. The second application falls on beverage cans. Aluminum displays better comprehensive property than many other metals like copper and magnesium. It weighs only less than one third of copper and a half of iron. In spite of lighter weight of magnesium, it loses battlefield to aluminum owing to small percentage of elongation. Aluminum boasts the best ductility in common metals, which makes aluminum slug for tubes satisfying material for beverage cans that require a lot about both ductility and anti-corrosion. In addition to food containers, small aluminum discs help to protect other household items as well. They are popular materials for power capacitor covers and toothpaste tubes.

Haomei Aluminum is an integrated manufacturer of aluminum sheet, aluminum coil, aluminum circle as well as aluminium slug for tubes. Welcome to contact us at april@aluminumhm.com or wechat/whatsapp +86 158 3802 9491 for more information!

Nydia

Nydia

Sales Manager

Sales Manager