Anod aluminum checker plate process

May 28, 2019

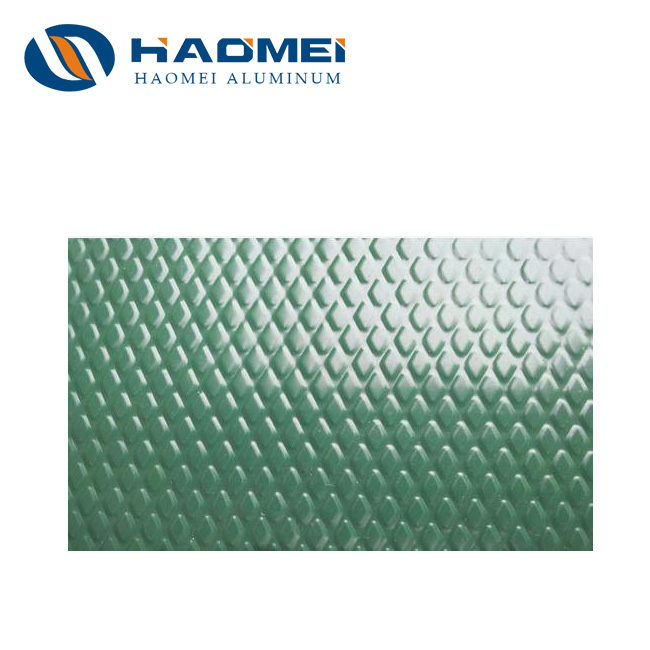

The anod aluminum checker plate refers to an anodized aluminum checker plate. The anodized method refers to the plating of a layer of dense alumina on the surface of aluminum and aluminum alloy to prevent further oxidation, and its chemical properties are the same as those of alumina. However, unlike ordinary oxide films, anodized aluminum can be dyed by electrolytic coloring.

The process for anod aluminum checker plates consists of six steps. The first is mechanical polishing, the second chemical treatment that removes copper of the surfaces, the third cleaning and degreasing (for parts that have been anodized, if re-anodizing is required, the original anodized surface layer is removed with alkali or special agent), the fourth oxide layer forming during which the aluminum checker plate is put into the dilute sulfuric acid as an anode, the fifth dyeing and the six fixing (heating or sealing the pores of the surface oxide layer with a chromate solution).

Anodizing can significantly improve the corrosion resistance, the surface hardness and wear resistance of aluminum checker plates. An anod aluminium checker plate has good decorative properties after proper coloring treatment. Aluminum and its alloy anodized film coloring technology can be divided into three types: chemical dyeing, electrolytic coloring and electrolytic overall coloring. Chemical dyeing uses the porosity and chemical activity of the oxide film layer to adsorb various pigments to color the oxide film. Electrolytic coloring is an alternating electrolysis of aluminum and its alloy in an aqueous solution containing a metal salt to deposit a metal, a metal oxide or a metal compound at the bottom of the porous layer of the oxide film due to the scattering effect of the electrodeposit on the light. Electrolytic overall coloring for the aluminum checker plate is divided into natural hair color, electrolytic coloring and power coloring method, in which electrolytic hair color dominates, natural hair color is second, and power color development is under development.

Nydia

Nydia

Sales Manager

Sales Manager