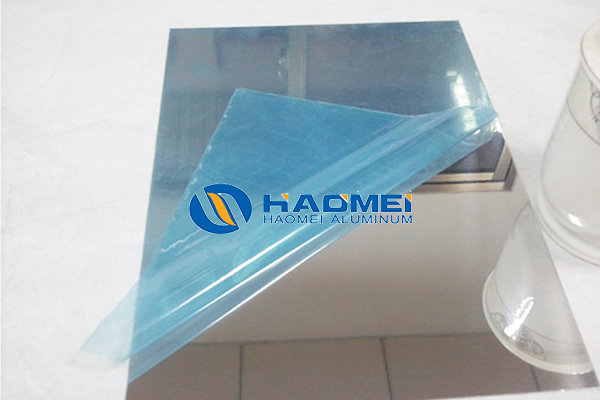

Aluminum light reflector sheet

February 6, 2020

An aluminum light reflector sheet is also known as an aluminium reflector sheet for lighting. Processed by rolling and grinding, the surface of the plate takes on a mirror effect. Mirror aluminum sheets can be cut into different sizes at will, boasting high strength, good electrical conductivity and super thermal conductivity. They have a smooth high-gloss surface that is easy to clean, widely used in lighting lamps, reflectors and lighting decoration, solar heat-reflecting materials, interior building decoration, exterior wall decoration, household appliance panels, electronic product housings, furniture kitchens, automotive interior and exterior decoration, signage, signs, luggage, jewelry boxes and other fields. Haomei mirror aluminum plates are of 1 series, 3 series, 5 series, and 8 series. The main alloy grades include 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3104, 3105, 5182, 5052, 8011, etc. The thickness range is 0.15-10mm, width 10-2650mm, and the reflectance as high as 80%.

1 series of aluminum light reflector sheets include 1050, 1060, 1070 and 1100. They are featured by high purity, single production process, relatively cheap price and an extensive scope of application. Most of the sheets in the market are 1050 and 1070 specifications The mirror aluminum 3 series are mainly represented by 3003, 3004, 3005 and 3105, the 5 series 5182 and 5052, and the 8 series 8011. There are many specifications and models, and clients should choose according to their actual production needs. Customized specifications are acceptable. There are some differences in price and use with these pieces of aluminium reflector sheet for lighting. Plates with low flatness can meet standards for regular home decoration, and those with medium and high flatness, like a 98 reflective aluminum sheet, are suitable for the outer packaging of high-end products. As for price, there are gaps, too. The purity of the 1-series mirror aluminum plate is relatively high, the production process is simple, and the price is relatively cheap. The 3 series mirror aluminum plate is an aluminum-manganese alloy, which has excellent anti-corrosion performance, and the price is higher. The main alloying element of the 5 series mirror aluminum plate is magnesium, and the representatives are 5657 and 5657 aluminum sheet plates. With low density, high tensile strength and high elongation, the 5 series mirror aluminum plates are more mature and expensive than the other two series.

The aluminum light reflector sheet produced by Haomei is light in texture, high in surface reflectivity, easy to form, and fine smooth in surface. It does not require pretreatment before processing and does not get scratched easily. Our mirror aluminum plates have a good application effect in lamps, reflective materials and other industries, and has been widely praised by customers!

Nydia

Nydia

Sales Manager

Sales Manager