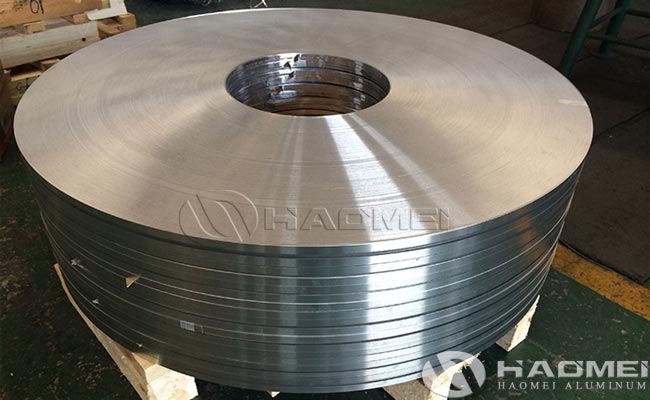

Aluminium Fin Coil

January 23, 2024

Aluminium fin coil 4343 and 3003 H24 are suitable for making cooking fins by any fin mill. Aluminum coil for fins meet the strength, plasticity, corrosion resistance, and weldability requirements of aluminum fin coil, while also providing good machinability and collapse resistance. These advantages make these two aluminum alloys ideal for aluminum fin coil manufacturing.

Aluminium fin coil 4343 and 3003 have good brazing properties, mainly due to their composition and process characteristics. These two aluminum alloys contain a certain amount of magnesium, manganese and other elements, which help to form a good brazed joint. During the brazing process, these elements react with the brazing material to form a strong metallurgical bond, thus achieving good joint strength. In addition, 4343 and 3003 aluminum coil alloys have good resistance to collapse, which is largely attributed to their strength and plasticity. During the brazing process, the shape and dimensions of the aluminum fin coil are susceptible to thermal deformation. However, due to the good plasticity and collapse resistance of these two aluminum alloys, they are able to withstand a certain amount of deformation without collapsing or twisting, thus ensuring the quality and stability of brazing.

Aluminum alloys 4343 and 3003 are widely used in the fabrication of aluminum fin coils because of their specific physical and mechanical properties. The reasons for using 4343 and 3003 aluminum coils for aluminum fin coils are as follows:

Aluminum alloy 4343 has good plastic processing properties such as forging properties, casting properties and extrusion properties. It also has good corrosion resistance and welding properties, as well as high strength and toughness. These properties allow 4343 aluminum alloy to meet the complex needs of aluminum fin coil, such as bending, crimping and forming.

Aluminum alloy 3003 is a commonly used rust-resistant aluminum with good plasticity and corrosion resistance. It is stronger than pure aluminum, but lower than other rust-resistant aluminum in the 4000 series. Due to its good machinability and corrosion resistance, 3003 aluminum alloy is commonly used to manufacture parts that require low strength and good corrosion resistance. In aluminum fin coil, 3003 aluminum alloy is usually used where moderate strength and corrosion resistance are required.

Nydia

Nydia

Sales Manager

Sales Manager