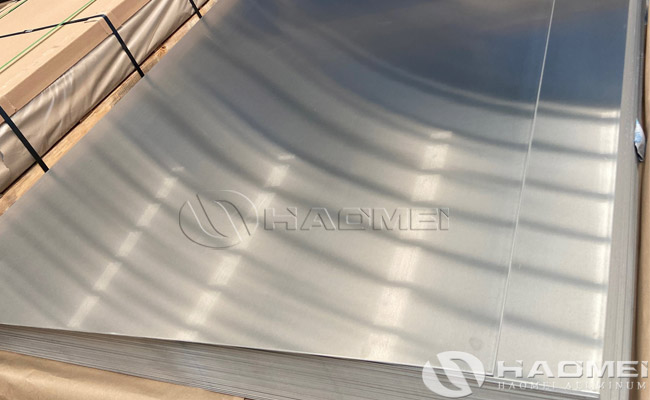

5052 H38 Aluminum Sheet

January 27, 2026

As engineers at Haomei Aluminum with years of experience in aluminum processing, we understand that 5052 H38 aluminum sheet is a core product in our export system, boasting both performance and compliance advantages. Essentially an Al-Mg series non-heat-treated strengthened alloy, it undergoes precise temperature-controlled annealing and full-hardness cold working. The magnesium content is stably controlled at 2.5%-3.5%, with minor adjustments of 0.15%-0.25% chromium, forming a uniform, fine-grained structure. This is the foundation of its performance and provides core support for subsequent process optimization and application adaptation.

In terms of core characteristics, the mechanical properties of 5052 h38 aluminum sheet are outstanding: tensile strength reaches 300MPa, yield strength 250MPa, and Brinell hardness is approximately 75HB, which is among the peak levels of the full-hardness state in the 5052 series. During production, we precisely control the reduction rate using a German SMS six-roll cold rolling mill, ensuring uniform stress distribution within the sheet. After stress release treatment, the flatness error is ≤0.5mm/m, solving the problem of deformation during thick plate cutting. Regarding corrosion resistance, the passivation film formed by magnesium resists marine atmospheric and salt spray corrosion. After 480 hours of salt spray testing, there was no significant pitting corrosion, far exceeding the standards for ordinary aluminum alloys.

Core advantages of 5052 aluminum sheet lie in process precision control and compliance adaptation:

- Process Precision Control:

Achieving high-precision control of magnesium content within ±0.05%, avoiding performance fluctuations from the source of composition. Welding strength reaches 92%-95% of the base material, superior to the industry average. Independently developed cold rolling process optimizes surface quality, with local defect depth ≤8% of plate thickness and total defect area <5%, allowing delivery of high-end orders without secondary grinding.

- Export Compliance:

Meets EU RoHS 2.0 standards (10 substances tested), with cadmium content ≤80mg/kg and lead content ≤900mg/kg. Simultaneously meets ASTM B209 and QQ-A-250/8 standards, allowing direct customs inspection in Europe, America, and Southeast Asia, saving customers additional compliance costs.

- Comprehensive Performance Advantages:

Compared to 5182 H38 aluminum, its elongation at break reaches 5.2%, achieving a balance between strength and formability. The cold bending radius coefficient can be controlled within 1.5 times the plate thickness, reducing processing losses for customers.

Application scenarios of 5052 h38 aluminum sheet precisely cover high-requirement fields:

- Shipbuilding and Marine Engineering:

Suitable for critical components such as ship decks and seawater pipelines. Targeted optimization of surface treatment processes results in an anodized layer thickness of over 15μm, significantly extending service life in marine environments.

- Automotive Manufacturing:

Adapted to fuel tanks and body structural components. Its lightweight characteristics contribute to vehicle weight reduction and fuel efficiency. A fatigue strength of 140MPa fully meets the automotive industry’s requirements for cyclic use.

- Construction and Decoration:

After textured embossing or anodizing, the products combine corrosion resistance with a decorative feel. A dimensional accuracy of ±0.02mm allows for precise adaptation to complex installation scenarios without additional adjustments.

Haomei Aluminum’s core competitiveness lies in continuous optimization of its operational processes: 3300mm wide hot-rolling production line enables mass production of all specifications from 0.2-150mm, avoiding splicing losses; each batch of 5052 h38 aluminum sheet products comes with complete compliant testing reports and material traceability certificates, efficiently solving export customs clearance pain points. This end-to-end control, from component management and process optimization to compliant delivery, allows products to truly achieve a balance between performance, compliance, and cost, building a differentiated competitive advantage.

Nydia

Nydia

Sales Manager

Sales Manager