Comprehensive Analysis of 5454 Aluminum Sheet Plate

January 19, 2026

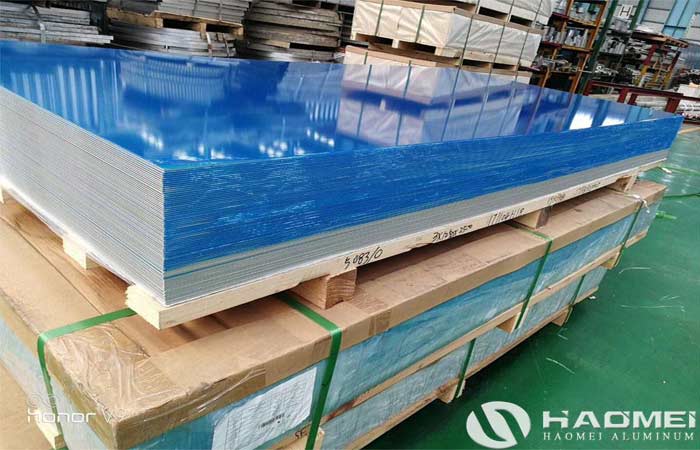

As a sales consultant for Haomei Aluminum, drawing on the company’s years of manufacturing and export experience in the aluminum processing field, this article provides a comprehensive analysis of 5454 aluminum plate, a high-performance alloy product. As a typical Al-Mg series rust-resistant aluminum alloy, 5454 aluminum sheet boasts balanced comprehensive performance and is widely used in many high-end fields globally, making it a core product in our export business.

5454 aluminum plate uses magnesium (2.4%-3.0%) as the core alloying element, combined with manganese (0.50%-1.0%) and chromium (0.05%-0.20%) to form a stable composition system, achieving excellent comprehensive performance without heat treatment. Compared to conventional 5052 aluminum plate, its strength is increased by approximately 20%, with tensile strength reaching 215-305 MPa and yield strength ≥85 MPa, while maintaining excellent plasticity and elongation up to 25%, achieving a balance between structural stability and processing flexibility.

Corrosion resistance is the core competitive advantage of 5454 aluminum sheet. This product effectively resists seawater, chlorides, petroleum, and various chemical liquids, exhibiting superior performance in complex environments such as stress corrosion, acid rain, and industrial pollution. Its service life is significantly longer than ordinary aluminum materials, making it particularly suitable for marine engineering and chemical industries. Furthermore, its weldability is excellent; after processing with TIG and MIG welding processes, the weld strength can reach over 85% of the base material, and it supports surface treatment processes such as anodizing, meeting both decorative and functional requirements.

Our company can provide 5454 aluminum sheets in various tempers, including O, H32, and H111, precisely tailored to the needs of different applications. The O temper offers excellent plasticity, suitable for deep-drawn parts and complex forming processes; the H32 temper, strengthened through cold working, boasts even greater strength, suitable for various load-bearing components; and the H111 temper retains the core properties after hot working, suitable for applications such as marine structural components. In terms of specifications, product thickness ranges from 0.15-600mm, width up to 3800mm, and length up to 16000mm. Custom production is supported, with a minimum order quantity of 500kg. In-stock supply is available to meet small-quantity purchase needs.

5454 aluminum sheet has a wide range of applications, covering tanker bodies, breakwaters, ship decks, pressure vessels, automotive fuel systems, and new energy battery housings. With its lightweight characteristic of 2.68g/cm³, it can achieve weight reduction of over 30% in equipment, significantly improving transportation efficiency. As a manufacturer with international authoritative certifications such as CCS, DNV, and ABS, our products undergo rigorous quality testing for each batch, accompanied by complete test reports and original factory warranties. Export customs clearance is efficient, with global delivery completed within 7-45 days.

Haomei Aluminum, with its mature production lines and vertically integrated supply chain capabilities, can handle bulk orders of 8-5000 tons, offering prices 10% lower than the industry average. Our company provides full-process technical support and customized services, safeguarding your projects from material selection and planning, processing and production to export logistics, helping global clients reduce costs and increase efficiency. Choose 5454 aluminum sheets, opting for Haomei quality, and empower your projects with high-performance aluminum materials to enhance efficiency.

Nydia

Nydia

Sales Manager

Sales Manager