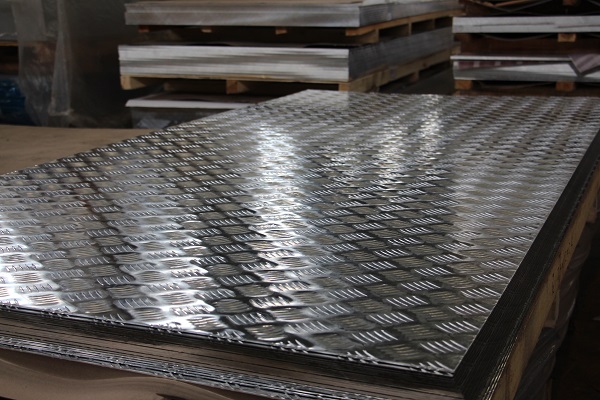

Chequered Aluminium Sheet

August 9, 2021

The pattern formed by the chequered aluminium sheet appearance is not only a decoration and beautification effect, but also bears the anti-skid effect in a special application environment, just as the clearer the texture, the stronger the anti-skid and grip capabilities of the tire. There are many types of checkered aluminum plate that can be used in different occupations.

chequered aluminium sheet

Usually aluminum alloy sheet, which is processed with the usual 1060 aluminum sheet as the material, has relatively low production and processing costs, and is suitable for indifference and vehicle floors under normal conditions; aluminum-manganese alloy sheet, which is made of aluminum-manganese alloy 3003 as the main material to be processed, has certain strength and impact resistance, and has certain anti-rust and anti-corrosion ability. 3003 aluminum checker plate is mainly used on the side of train cars; aluminum-magnesium alloy sheet is processed from aluminum of 5052 or higher. With high strength and hardness, rust and corrosion resistance is very strong, and can be used in ships and even aerospace industries.

The chequered aluminium sheet produced has a novel structure and good anti-skid effect. The introduction of internationally leading Italian Herkues grinding machine equipment ensures that the work rolls on the rolling mill can be regularly and meticulously ground, so that the rolling equipment can operate accurately and improve the surface quality of the product. The finished aluminum chequer plate product is lighter in weight and has excellent durability. The mass per square meter is about 7kg, its tensile strength reaches 200N per square millimeter, the aluminum plate has high elongation, and the relative elongation is higher than 10%. It can withstand high bending without breaking and has good toughness.

Nydia

Nydia

Sales Manager

Sales Manager